In 1970, a Japanese company called Toray created Ultrasuede®, a non-woven polyester/polyurethane fabric designed to mimic actual suede. And did it ever! It looked and felt like the real deal and it was available by the yard in a host of fashion colors and with no imperfections.

Since the debut of Ultrasuede, other manufacturers have created a variety of synthetic suede fabrics, some woven, some knitted, and others non-woven, mimicking the coveted faux.

Know your suede

Ultrasuede and other imitation suede fabrics come in multiple weights, depending on the use, but for fashion and accessory applications, there are many to choose from. It’s a good idea to store suedes on a roll instead of folding, as some creases are hard to remove.

Ultrasuede is not very flexible, so it’s best suited for simple pattern designs. It doesn’t ease well, so look for raglan or cut-on sleeve designs. Try to avoid darts, as subtle shaping isn’t one of its virtues. Other suedes may be more drapable, so choose construction details accordingly.

Needle holes tend to show in faux suedes, so be sure to make a muslin and do fitting adjustments before cutting to avoid ripping out. Likewise, pin holes may be permanent as well, so use weights for cutting to avoid lasting marks.

On non-woven suedes, use a low-temperature fusible interfacing and steam. A press cloth is essential to avoid damaging the surface. Most suedes can be pressed with an iron on a synthetic temperature setting.

Cutting

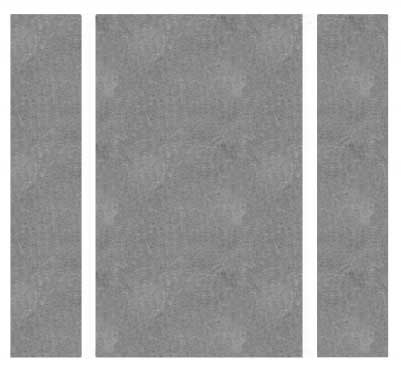

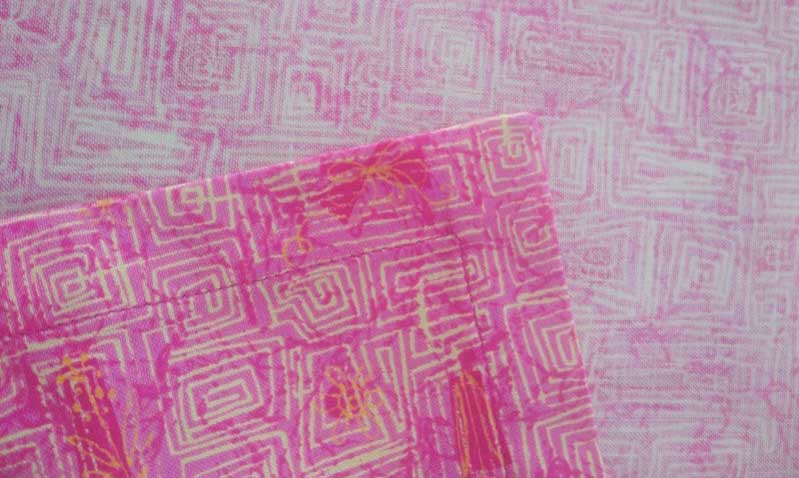

All suedes have nap, meaning that the shading changes depending on the fabric’s direction. Nap going up creates a darker look, while down-facing nap creates a lighter coloration. Choose one and stick with it for the entire project. Mark chalk arrows on the fabric wrong side to show the direction.

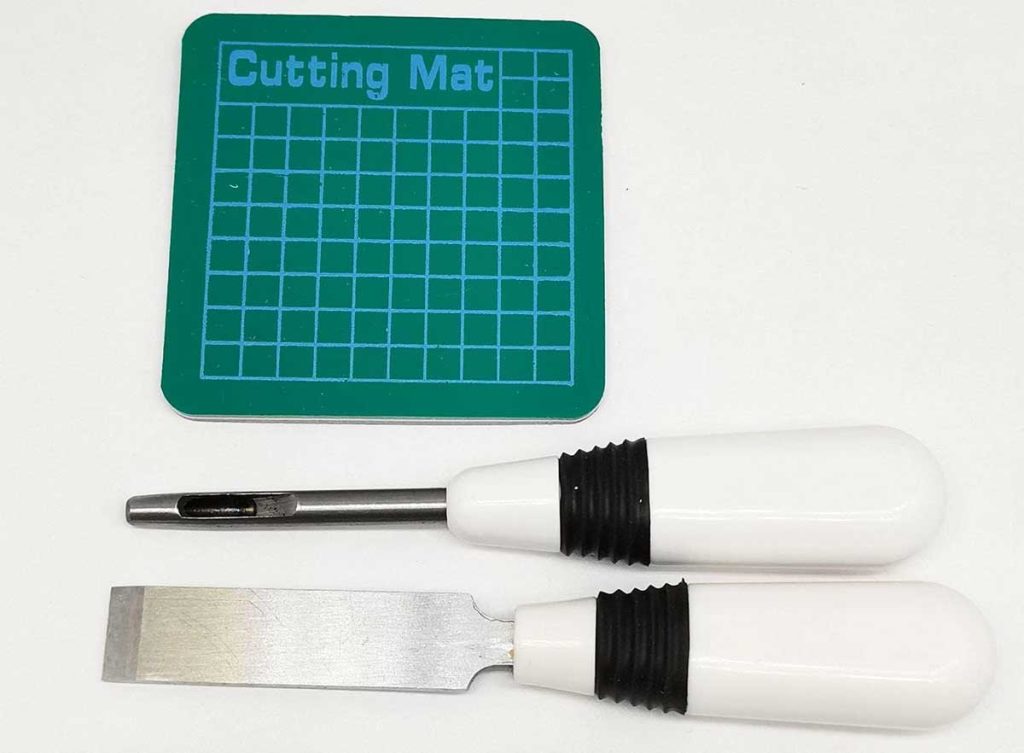

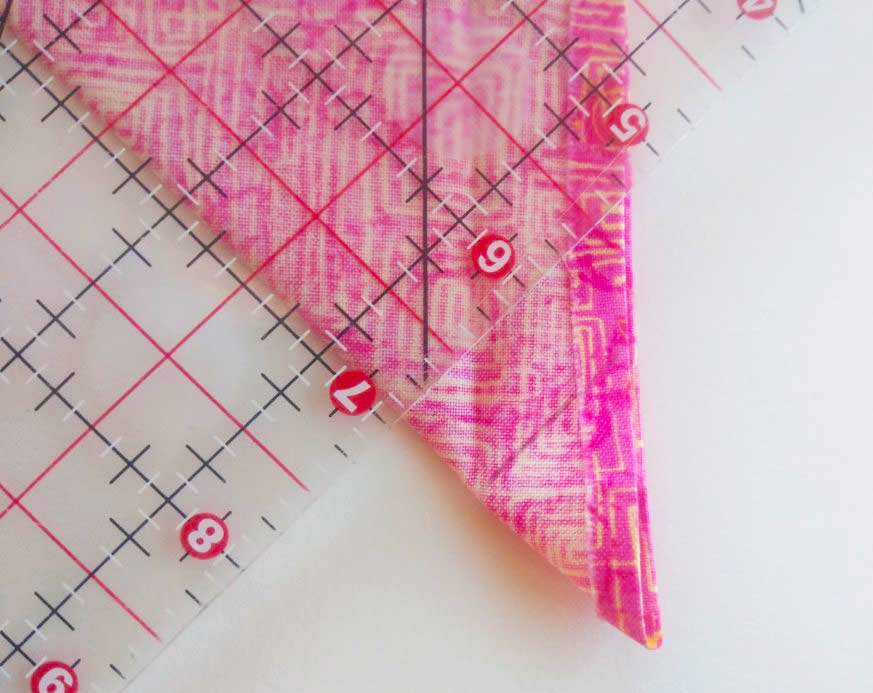

On heavier non-wovens, it’s best to cut your pieces on a single layer of fabric, rather than folded. Make a whole pattern piece from paper for easier cutting. For the cleanest cutting line, use a rotary cutter and mat, rather than scissors.

Sewing

Contrary to what you might think, don’t use a leather needle, as the specialty wedge point will leave permanent holes in your seam. Instead, use a size 80/12 Universal needle. If your test stitching shows skipped stitches, switch to a stretch needle.

- Lengthen the stitch length for sewing—to about 3mm for seaming, and 4-5mm for decorative topstitching. Sew with regular-weight thread.

- A walking foot is very helpful to keep layers even. Coupled with clips to hold multiple layers in place, there’s no risk of damage from permanent pin holes.

- If your presser foot tends to stick to the suede, change to a non-stick foot instead to glide over the surface. Don’t have one? Put a piece of tape on the underside of a presser foot and make a needle hole in it.

- A technique called taut sewing is helpful on most suedes. This means holding the fabric in front of and in back of the presser foot, but not stretching it, as you sew. This is especially helpful on lighter weight suedes that may tend to poke down into the needle hole or pucker.

Seaming options

There are multiple ways to seam these nappy fabrics, depending on the character and construction.

Abutted seam: Use this seam in areas with no stress. Trim adjacent seam allowances and abut the edges, then stitch with a multiple zigzag or other decorative stitch that catches both edges.

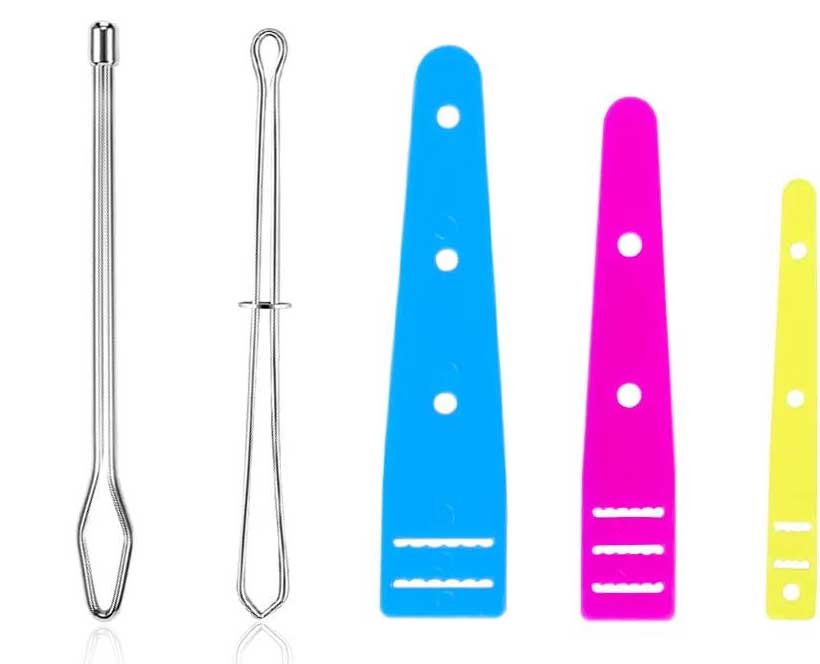

Lapped seam: Trim the seam allowance from the overlap edge (cleanly or decoratively); overlap the trimmed seam to the seam allowance of the adjacent piece and stitch—once or twice. Water-soluble basting tape is ideal for keeping the edge in place during stitching.

Topstitched open seam: Sew a traditional seam and lightly press the seam allowances open. You can fuse it in place with a narrow line of web or fusible thread. Topstitch both sides of the seam.

Topstitched one direction seam: Sew a traditional seam and press the seam allowances in one direction. Topstitch.

On the Edge

If your non-woven suede project includes some single-layer edges, it’s easy to trim them using decorative scissors or a specialty rotary cutter blade. These suedes don’t ravel, so no worries. Think about a pinked, scalloped or wavy edge, or just leave the cleanly cut edge.

~Linda Griepentrog is the owner of G Wiz Creative Services and she does writing, editing and designing for companies in the sewing, crafting and quilting industries. In addition, she escorts fabric shopping tours to Hong Kong. She lives at the Oregon Coast with her husband Keith, and three dogs, Yohnuh, Abby, and Lizzie. Contact her at .