How do I?

Sewers can frequently say these three simple words to other sewers, and it’s often at an ASG meeting, get together, or workshop. Most times the answer is simple and readily shared by perhaps a more experienced sewer. We’ve received some of those questions, and we’ve got some answers.

HOW DO I…make piping so that the stitching doesn’t show when I insert it?

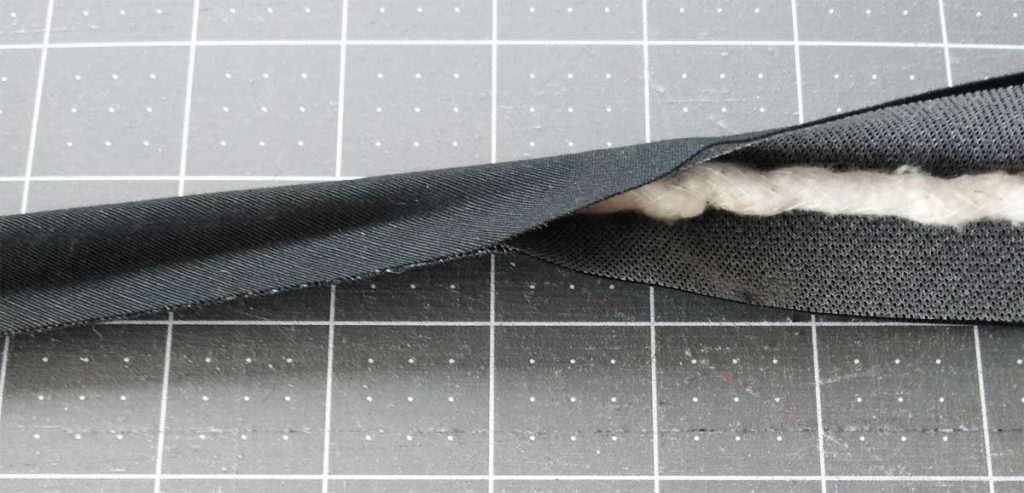

The easiest way to solve this dilemma is to not stitch it when you’re covering it! Measure the circumference of your piping filler cord and add 1 ¼” for seam allowances. Cut your piping covering fabric to that width by the amount of length needed, plus an extra inch or two. This fabric can be cut on the straight grain or bias, depending on where the piping will go and the desired finished look. If it goes around any curves, cut the covering fabric on the bias.

Cut a strip of fusible web the same size as the covering fabric, noting that it may be necessary to abut the ends to get the length needed.

Place the fusible web on the wrong side of the fabric strip and wrap it around the filler cord. Using the tip of your iron, press the long raw edges of the piping covering together, snugging the fabric up to the cord. During insertion, use your zipper foot and adjust the needle position so it’s as close to the cord as possible for perfect piping.

HOW DO I…finish the seam allowances of an unlined jacket made from a ravelly fabric like silk suiting?

One of the easiest and nicest looking methods of taming a ravelly suiting is called a Hong Kong finish. It’s easy to do and makes the inside of your jacket look stunning.

Begin by choosing a binding fabric—it can be a color match to your garment, or a stark contrast if you prefer; it can be solid or print, depending on how much pizazz you want on the inside. Lining fabric works well for this technique as it’s lightweight, but you can also use lightweight cotton.

Cut bias binding strips 1” wide (1 ¼”-1 ½” for bulky garment fabrics). This allows you to bind both straight and curved seams without puckers. Piece the strips together with diagonal seams to get the length needed and press those joining seams open.

Press the seam allowances of the jacket open (except armholes). On armholes, press the seam allowances in one direction and bind the two edges together. Pin the binding to a single layer of the seam allowance, matching the raw edges. Sew with a ¼” seam allowance being careful not to stretch the binding. Press the binding away from the seam, and fold it snugly over the seam allowance edge, then pin in place. Stitch in the ditch of the seam to secure the binding underside. Press, then trim off any excess binding width on the wrong side, leaving about 1/8” beyond the stitching.

Quick Tip: For even faster binding, use fusible thread in the bobbin for the initial stitching line, then fold the binding strip over the seam allowance edge and press to hold it in place.

This technique can also be used on facing, pocket and hem edges for a beautiful inside finish. And it can be used on reversible garments as well—instead of stitching in the ditch of just the single-layer seam allowance, stitch through the entire garment to flatten the seam. One side will show topstitching and the other side will show the finished seam allowances.

HOW DO I…make a pompom for a fleece hat?

Fleece makes great pompoms because it doesn’t fray, so all you have to do is cut. Decide on the finished size of your pompom and cut 30 fleece strips ¼” wide by the length you determined. Cut an extra ¼” strip about 8” long. So, for a 4” pompom, you’ll need thirty 4” x ¼” strips and one ¼” x 8” strip.

Stack up the like-size strips directly on top of each other and use the longer strip to tightly tie the center of the stack together; knot securely. Fluff up the pompom and use the longer strip end to attach the pom to the hat—either in the seam as you’re constructing it or threaded into a tapestry needle and attached after construction.

If desired, clip the ends of the pompom strands at an angle.

~Linda Griepentrog is the owner of G Wiz Creative Services and she does writing, editing and designing for companies in the sewing, crafting and quilting industries. In addition, she escorts fabric shopping tours to Hong Kong. She lives at the Oregon Coast with her husband Keith, and three dogs, Yohnuh, Abby, and Lizzie. Contact her at gwizdesigns@aol.com.