Should quilt bindings always be double?

Quilt bindings can be single or double layer, depending on preference, but it’s worth noting that single-layer bindings do not offer as much “protection” to the quilt edge as double-layer ones do. If a quilt is going to be used regularly and/or washed, the added layers of a double binding will wear longer. A single-layer binding is often used on smaller items like table runners and wall hangings and it reduces bulk in comparison to the double-layer binding.

Quilt bindings can be single or double layer, depending on preference, but it’s worth noting that single-layer bindings do not offer as much “protection” to the quilt edge as double-layer ones do. If a quilt is going to be used regularly and/or washed, the added layers of a double binding will wear longer. A single-layer binding is often used on smaller items like table runners and wall hangings and it reduces bulk in comparison to the double-layer binding.

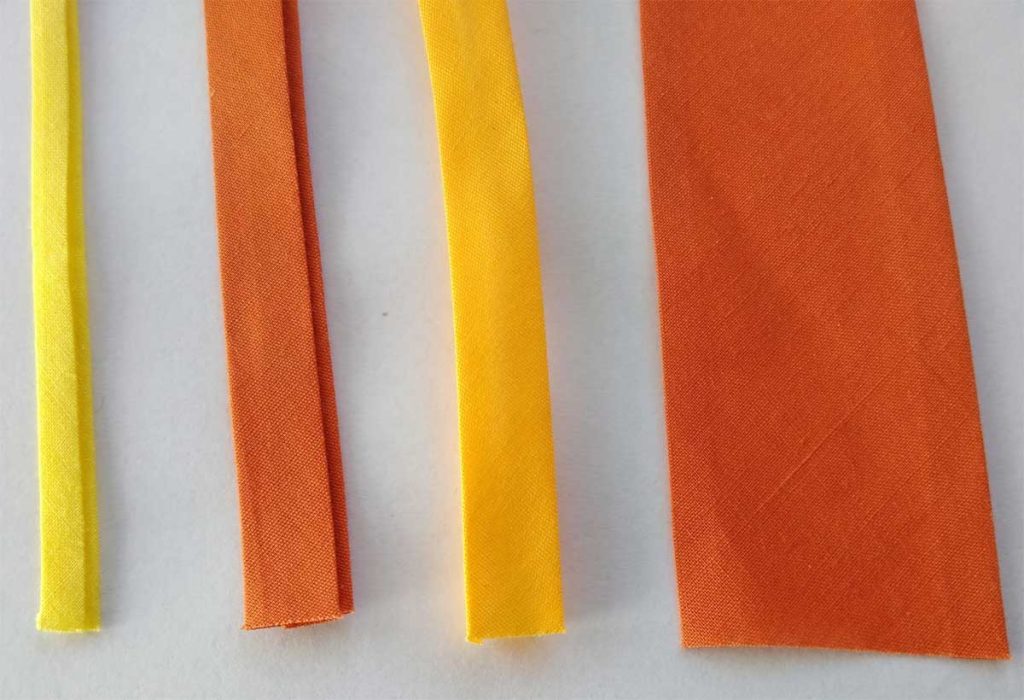

A double-layer binding is usually cut 2 ¼” to 2 ½” wide, folded wrong sides together and both raw edges aligned with the right side of the layered quilt edges for application with a ¼”-wide seam allowance. Once the initial stitching is completed, the binding is turned to the quilt underside and the folded edge is hand- or machine stitched on the quilt underside.

A single-layer binding is usually cut 1 1/4” wide. The long raw edge is aligned with the layered quilt edges, stitched in place and then the remaining raw edge of the binding is turned under ¼” and hand- or machine stitched in place on the quilt underside.

Both single- and double-layer bindings should be tight to the edge and completely filled with the quilt layers. Some quilters like to leave a little extra batting extending beyond the true edge of the quilt as additional filler inside the binding.

What is the easiest style of quilt to make for beginners?

One of the easiest quilts for beginners is one where no adjacent seams need to be matched, and seams are sewn in a straight line.

One option for easy beginner quilts includes offset blocks, where the squares (or rectangles) are cut all the same size, sewn together in strips and placement is offset. No seam matching required.

Another easy option is strip quilting with 2 ½” (or wider) strips cut the full width of the fabric. The long edges are sewn together with straight seams, and strips added to create the desired size quilt. This creates a quilt approximately 42” wide. Strips can be sewn together end to end to make a wider quilt top and/or borders can be added to the outer edges to create the desired size.

After trying these two techniques, novice quilters can “graduate” to more complicated patterns with more complex cut shapes and seam matching required.

All quilting projects, no matter how simple, require accurate cutting of all pieces so they fit together, followed by accurate stitching of seams. A quarter-inch presser foot for the machine is helpful as it has a vertical guide for the fabric edge to follow. Or, the distance from the needle to the edge of another presser foot may be exactly ¼” so the foot edge can be used as a guide for even seaming.

Many years ago when I bought quilting fabrics, the clerk tore them. They don’t seem to do that anymore—why?

Those of a certain age may remember when fabric was drawn through a Measuregraph machine that measured the fabric and made a little slit at the designated amount and then the piece was torn off the bolt. Always a bit off-putting to see new fabric torn, most stores today simply cut it with scissors or a rotary cutter.

Tearing fabric does indicate the grainline, but it also can also distort it and leave white lines along the tear line, depending on how the fabric was printed. Those white streaks have to be cut off. Some prints are not aligned with the fabric grain, so tearing makes that much more obvious and creates waste for sewers trying to align the pattern with the block cuts. In addition, some fabrics simply cannot be torn—those include synthetics, knits and novelty weaves.

So, cutting seems to be a better option for today’s fabrics.

What color thread should I use to sew a quilt together when the fabrics are all different colors?

When piecing a quilt, choose a neutral color thread like beige, light grey, white or off-white. These blend with a variety of light- to mid-tone fabric colors. If your quilt is predominately dark colors, a black, brown, navy or dark gray may be more suitable for seaming.

If your machine tension is properly adjusted, the stitching in your quilt seams won’t show anyway and it will meld into the fabrics.

For the actual quilting process, the thread color depends on how prominent you want the quilting design to be—a contrast color will make it more prominent, while a neutral will make it less prominent. Or, choose a variegated thread and get the best of both. If you want the quilting to totally disappear visually, choose a monofilament.

Some quilters like to use a bobbin thread to match the quilt back, but be sure your machine tension is well adjusted if you choose this option so that the bobbin thread doesn’t peek out on the top side.

~Linda Griepentrog

Linda is the owner of G Wiz Creative Services and she does writing, editing and designing for companies in the sewing, crafting and quilting industries. In addition, she escorts fabric shopping tours to Hong Kong. She lives at the Oregon Coast with her husband Keith, and two dogs, Yohnuh and Abby. Contact her at .

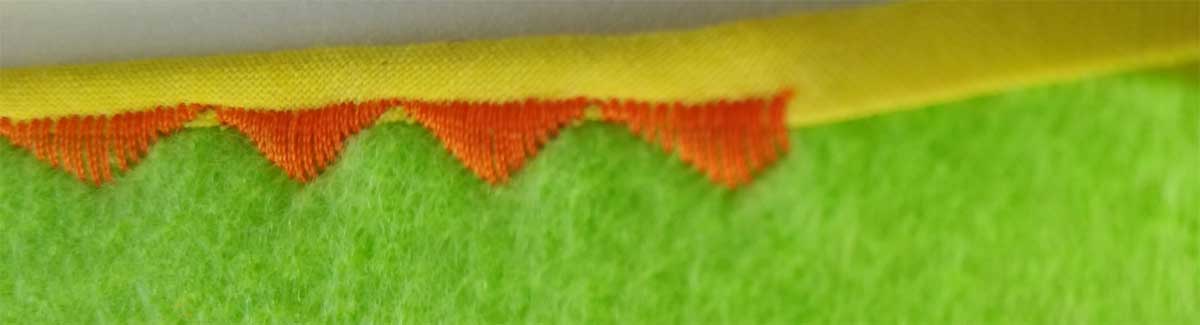

Now that we’ve got your attention, let’s talk about this uncommon notion called horsehair braid!

Now that we’ve got your attention, let’s talk about this uncommon notion called horsehair braid!