Welcome to Carolyn Chen, our newest member on the ASG National Board of Directors!

Carolyn has been an ASG member since 2001 in the Nassau-Queens, NY chapter and held offices of President, Newsletter Editor, Treasurer, and Secretary. More recently she served as president of the Salt Lake City Chapter.

Carolyn learned to sew as a 4-H member in Long Island, New York. Having the solid foundation with the 4-H training, she additionally credits the many classes she has attended through ASG Conferences and various stitching expos with elevating her skills and creative pursuits.

Carolyn learned to sew as a 4-H member in Long Island, New York. Having the solid foundation with the 4-H training, she additionally credits the many classes she has attended through ASG Conferences and various stitching expos with elevating her skills and creative pursuits.

On her day jobs, Carolyn has held engineering and management positions which gave her experience in project planning, meeting deadlines, public speaking and communicating with team members. Over the years of living through roller-coasters of company buyouts and mergers, she decided to explore alternative professions as a backup and signed up for two semesters at the Maison Sapho School of Dressmaking and Design in New York City, in 2008. There, she studied French dressmaking, design by draping, and hand embellishment techniques in the European traditions. The curriculum was demanding and educational, yet was an exercise in intellectual submission.

At the Maison Sapho School, I quickly realized that the headmistress expected work to be done by traditional methods, so all of the nifty tips picked up at ASG conferences had to be ignored for class homework. For example, the use of fusibles was forbidden and passionately demeaned.

Carolyn retired to Salt Lake City, Utah in 2011 where there is very strong crafting and DIY community. Joining the Salt Lake City ASG chapter, as well as the Knitting Guild, and Wasatch Woolpack Handspinners (yarn spinning) made the cross-country move very enjoyable for her and she now enjoys sharing creative ideas with others. A trivia joke amongst her friends is, “How many guilds does Carolyn belong to and how many offices does she hold?”

Coming out of retirement in 2016 to support her nuclear family (husband and dog) when an in-law became terminally ill, she found that working cut back on her social daytime craft networking and neighborhood group participation. However, it was nice to have more disposable income for Stash Accumulation. The problem now is that it isn’t just fabric, it’s yarn, raw materials, and dyes to make yarn. You have all been asked, “How many sewing machines do you own?” Carolyn also has to answer, “How many spinning wheels and looms do you own?”

For Carolyn, every bit of fiber training comes in handy as there is crossover in all of her craft disciplines. Understanding ease in garments, taking measurements, pattern drafting, piecing, fabric characteristics for intended use, and construction for stability get put to use in sewing, knitting, weaving and spinning a finished product.

Carolyn’s second retirement was welcomed at the end of 2019 which gave her more time to work on that SABLE: Stash Accumulation Beyond Life Expectancy, and more time to devote to the American Sewing Guild on the Board of Directors. With all of her talent, she is sure to be an asset to our national board.

We’re glad to have you with us, Carolyn!

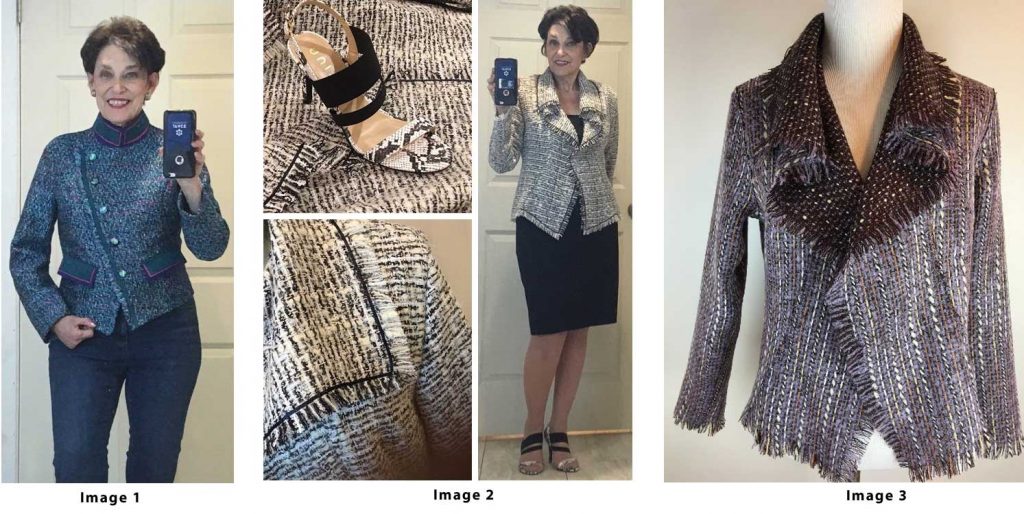

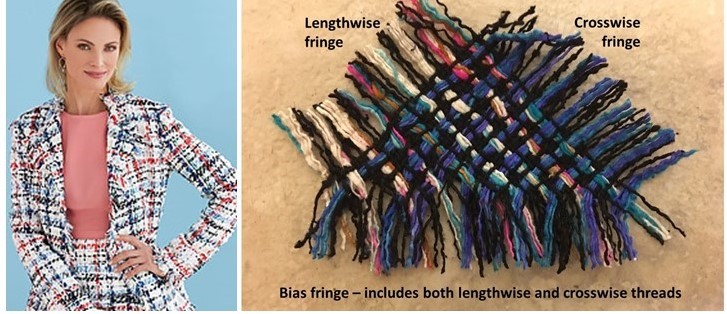

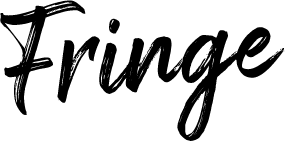

Fringe, whether you choose to love it or leave it, has undoubtedly stood the test of time. Dating back to 3000 B.C. in Mesopotamia, fringe became popular as a fashion embellishment in the 1920’s, then resurfaced again in the 50’s, and came full circle in the 60’s, 70’s and 80’s. Popular again today, it can be casual and trendy or utterly timeless, like in the garments shown here. Enjoy some ideas from Nancy Nix-Rice on these beautiful fringe accents.

Fringe, whether you choose to love it or leave it, has undoubtedly stood the test of time. Dating back to 3000 B.C. in Mesopotamia, fringe became popular as a fashion embellishment in the 1920’s, then resurfaced again in the 50’s, and came full circle in the 60’s, 70’s and 80’s. Popular again today, it can be casual and trendy or utterly timeless, like in the garments shown here. Enjoy some ideas from Nancy Nix-Rice on these beautiful fringe accents.