Japanese Tailoring: What is it? Japanese tailoring represents a distinctive approach to construction methods within Japan’s ready-to-wear clothing sector. This method seamlessly blends the intricate craftsmanship of traditional tailoring with the efficiency and accessibility of modern techniques, resulting in impeccably crafted garments. These are a few of the characteristics found in Japanese tailoring techniques: Fusible […]

Quilting Q&A: Borders, Miters, and Fussy Cuts

Today we offer a triple treat of quilting trivia. From understanding mitered corners, to explaining fussy cuts, and finally, navigating the width of a quilt border. Grab your rotary cutter and let’s patch together some knowledge that’s as snug as a perfectly quilted blanket! How wide should a quilt border be? A quilt border can […]

Add a Little Bling: Iron-on Designs

Whether you’re planning to bling out a ready-made T-shirt or denim jacket, or you’re planning to embellish a garment you’re constructing, iron-ons can help you become an artist. Iron-on designs are available with small, single motifs, or more elaborate large designs, depending on your preference. Pre-made designs are temporarily affixed to a paper or plastic […]

Seam Finishes

We often don’t think about seam finishes when constructing a new garment. A standard straight-stitched seam may be your go-to technique, you may zig-zag the seam and trim close to the stitching, or you might use your serger to provide a clean and easy finish. While any of these methods are efficient and give a […]

Fabric Napkins: A Square Deal

Fabric napkins are a fun way to add some style, color, or interest to your dining table, whether casual dining for the family or more formal affairs for guests. There’s a perfect fabric for all occasions, and they’re sew easy to make, even a beginner can create them. Once you start, you can’t stop! Napkins […]

Altering Your View of Sewing: Upcycling

With ASG’s inaugural Sustainable Sewing group meeting less than a week away, this timely article will help encourage you to start thinking about sustainable sewing opportunities for your wardrobe. We often think of repurposing thrifted materials — whether it be fabric scraps, curtains, or clothing — into non-clothing items like handbags, dog beds, or home […]

Sewing Back to Basics: Gathering

Gathering is one of many ways that parts of a garment (or other project) can be joined together when one portion is larger than the other. Sometimes this task is accomplished with pleats or darts, but often gathering is the most used option. Think of a gathered skirt joined to a fitted bodice, or a […]

See Before You Sew

Selecting the ideal fabric for a garment tailored to your preferences and body type is a frustration that even the most experienced seamstresses encounter at least once, if not multiple times, in their sewing journey. Many of us also inadvertently create additional hurdles for ourselves when aiming for the absolute perfect garment. In our pursuit […]

2024 Conference Fashion Show Entry

Fashion by the Bay Dive into a colorful tapestry of creativity as you join other ASG members on the grand stage at this year’s Conference. Whether you’re into everyday chic, athleisure comfort, vintage vibes, upcycled treasures, ethnic flair, lounge wear, or special occasion wear, the spotlight is yours. Let your imagination run wild because there’s […]

Sew Much Fun Tour: Hong Kong

Sew Much Fun Hong KongDecember 3-11, 2024 Travel is good for the soul…and it’s good for the fabric stash as well. Who among us hasn’t Googled “fabric stores” when we’re headed to a new city? Or even a new country? We have a never-ending sense of curiosity and seem to be afraid of “missing something.” […]

Charitable Sewing: Cause and Effect

We all love to sew but sometimes you want to switch up your sewing projects beyond your own clothes, quilts, or placemats. What do you do? Look for opportunities to share you sewing skills with others in need. Donating your time and talents is a selfless act. While your donation makes a direct impact in […]

Hideaway Ideas for Small Sewing Spaces

As creative as we are with our sewing skills, sometimes we also have to get creative with our sewing space. A large, dedicated sewing room is every sewist’s dream, but finding the perfect sewing furniture for small spaces can be challenging, especially if it needs to blend with your living room, dining room, or bedroom […]

Presser Foot Fun: Non-Stick Machine Feet

Nothing is more frustrating than uneven stitching—your thread stitches can go from long to short in an instant, ruining your line of topstitching or seaming. In severe cases, the wickedly short stitches can damage fragile fabrics by creating a hole, and some fabrics don’t take kindly to ripping out stitching and beginning anew. Stitching in […]

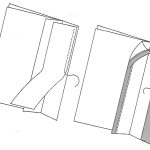

Sew an Easy Sleeve Placket

A sleeve placket is that nifty little opening at the bottom of a sleeve, skillfully stitched to let your hand slip through with ease. Typically, you’ll spot it on shirts or blouses, and it’s usually topped off with a neat cuff. Beyond its practicality, the placket can also be a real style statement. Ever thought […]

Zippers with ZIP!

Zippers don’t have to be under flaps—they can be showcased on the outside of a project and embellished as well. It’s All About the Stitches You know all those stitches in the machine that you admire, but may not use often? Many of those are perfect to highlight an exposed zipper. Just pick one that’s […]

- 1

- 2

- 3

- …

- 24

- Next Page »