While miters may serve as a basic way to clean-finish garments, they are just cool enough to think about using as embellishments. Why not feature them on your garments and show off your skills? It’s fun to use a normally utilitarian technique as an artistic detail.

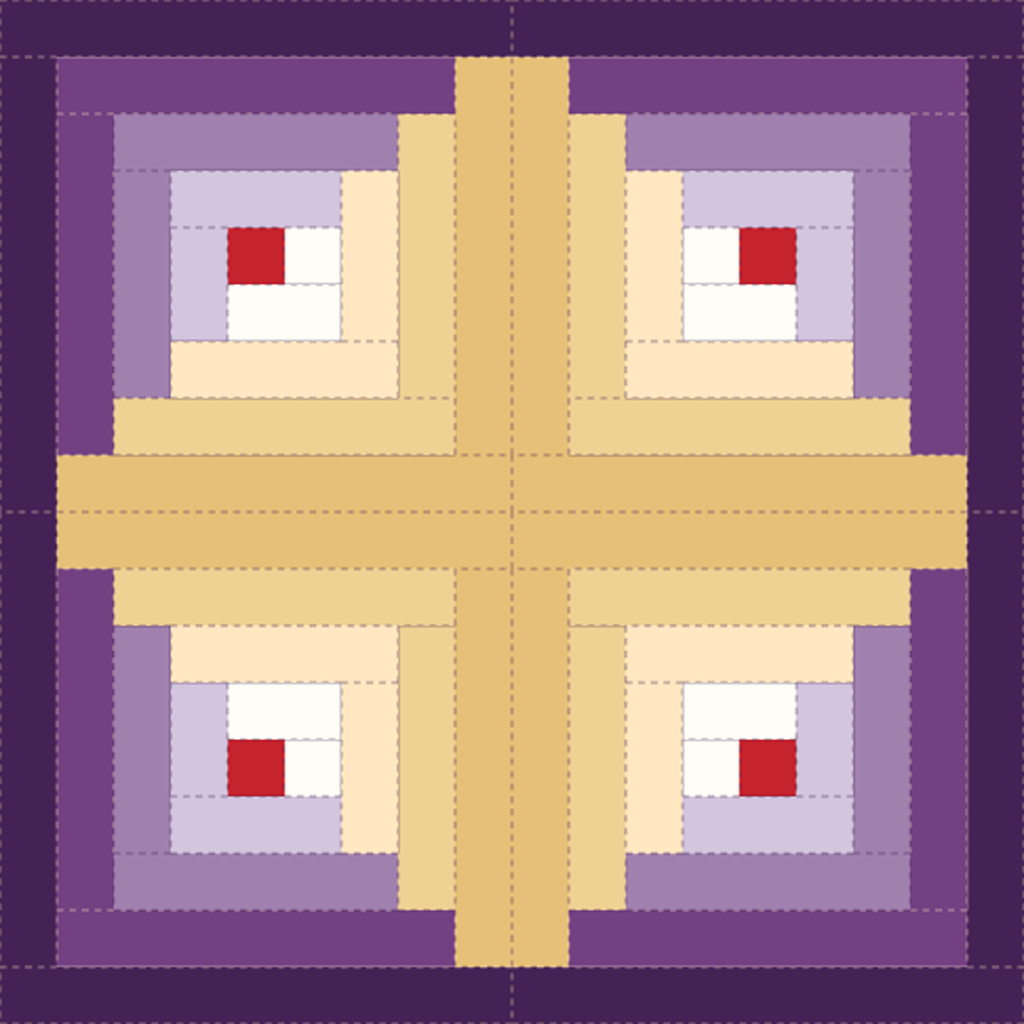

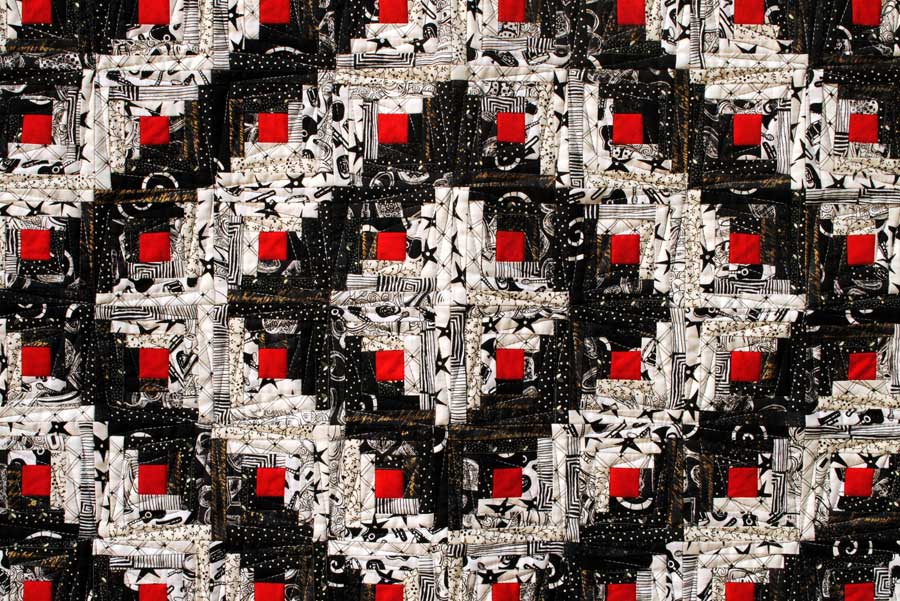

There are three miter techniques that lend themselves to embellishing ideas. What is so appealing about these are the possibilities of using really “out-there” fabrics and trims: print fabrics that are too gaudy to wear as a total garment, but great when reduced to a narrow strip; stripes that can run vertically or horizontally to meet creatively at corners; shiny fabrics to use with matte-finished fabrics; bubbly textures on smooth fabrics; or reversible fabrics that show off their contrasting wrong sides when turned. Those orphan fabrics in your stash may be just the ticket for some wonderful binding.

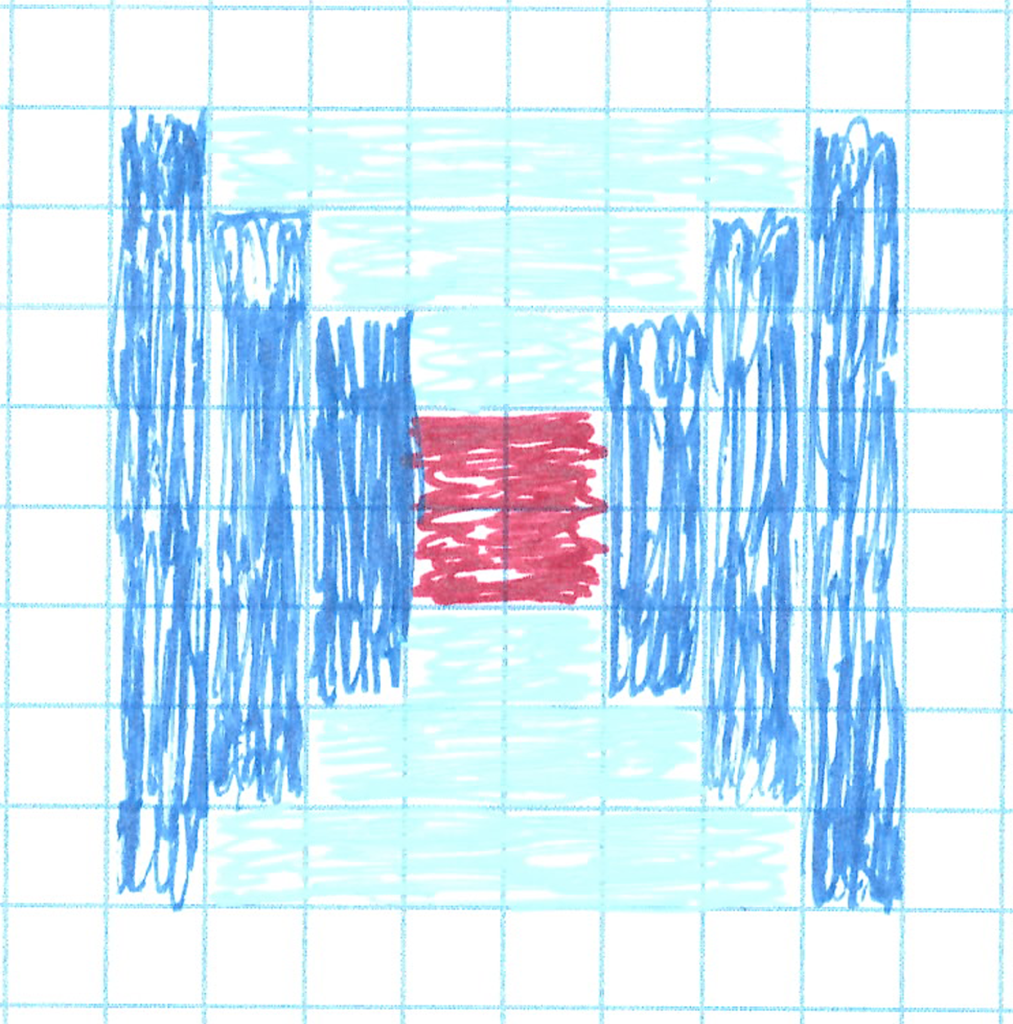

Mitered Binding

Traditional binding is a method of covering an edge that encases the raw edge and looks attractive on both sides. It eliminates the need for hems and/or facings and it adds the punch of trim to both the inside and the outside of the garment.

Binding is applied before intersecting components, such as facings, collars, or waistbands, are attached to the garment or before other elements, such as hems, are finished. It is most commonly cut on the bias so that it fits easily around curves and corners. But if you are dealing with straight edges and right-angled corners, a binding can be cut on the straight of grain. It will certainly be easier to handle; it may also be a more economical use of fabric.

Getting started

Whether you’re working with bias or straight grain strips, the first step is to determine how wide you want the finished binding to be. A binding can be any width from very narrow, such as 1⁄2″ wide, to several inches wide—it’s all about the effect you want to achieve. The width of your strips needs to equal four times the finished width.

The next step is to determine how much binding you need. Measure the length of the edge(s) you are covering with binding. If you are adding binding as an edge finish to a pattern that doesn’t call for it, trim off the seam allowances along the edges to be encased in binding and then measure.

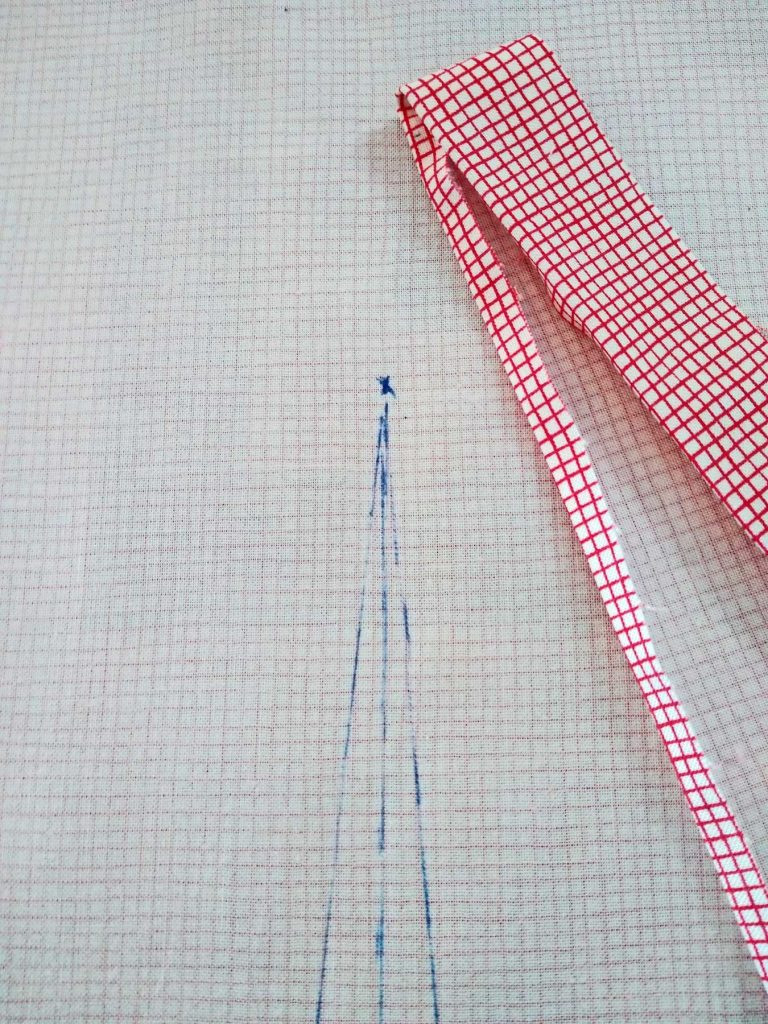

Once you’ve determined how much binding you need and how wide it should be, cut and join enough fabric strips to make a continuous piece of binding that is the required length plus a few extra inches. Use 1⁄4″ seams to join the strips.

- Press the binding in half lengthwise, wrong sides together. Then press the seam allowances to the inside of the binding so that they meet at the center crease.

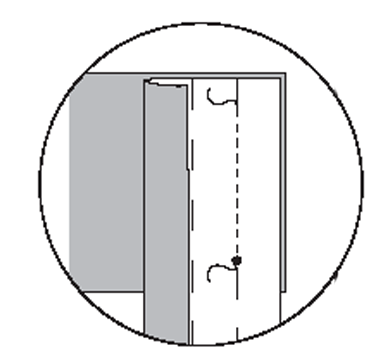

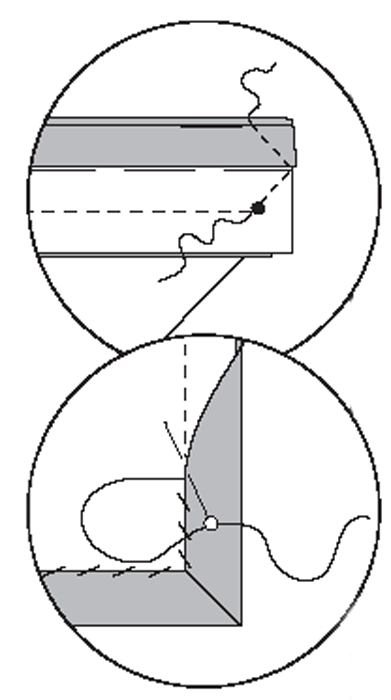

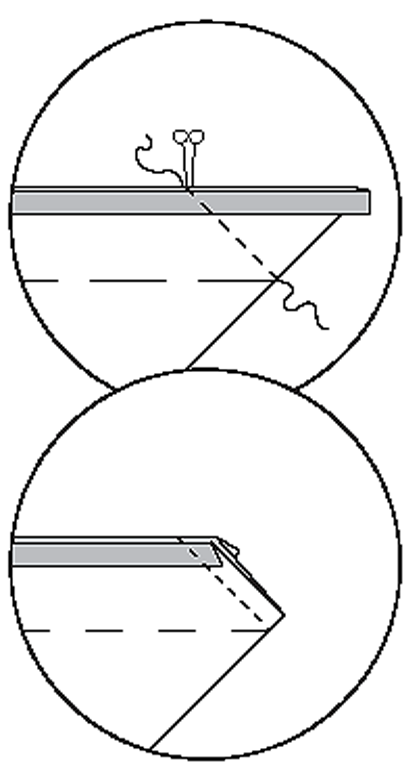

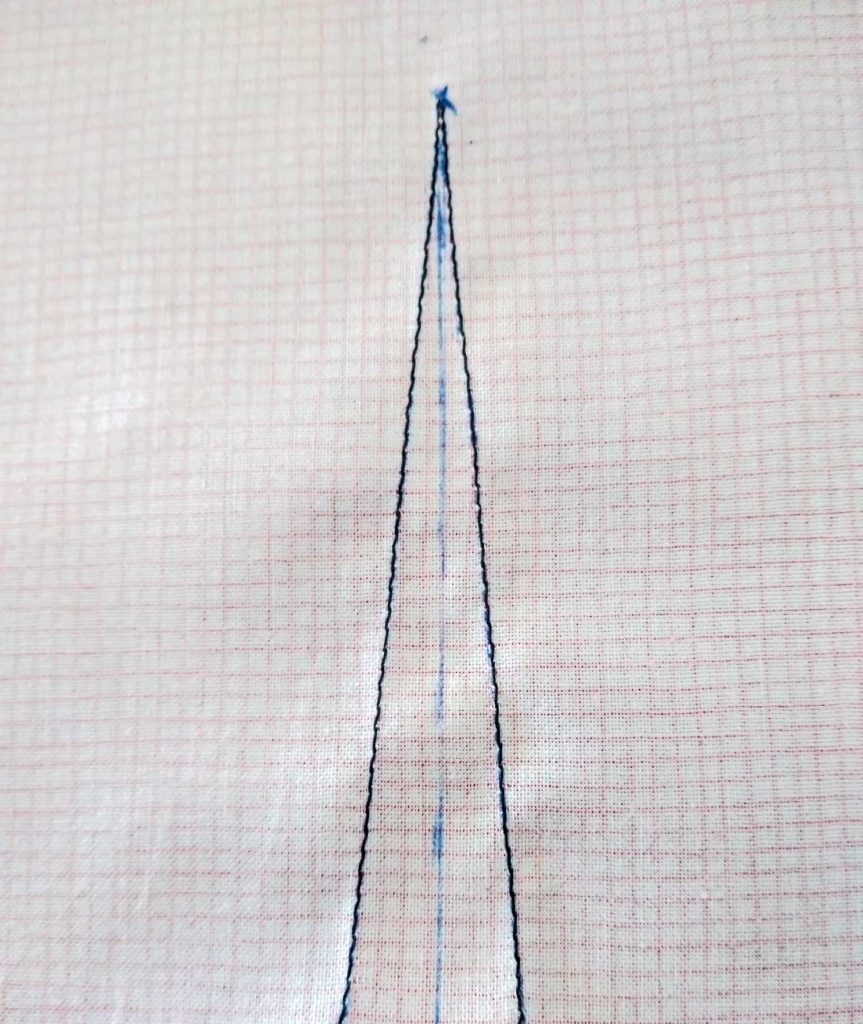

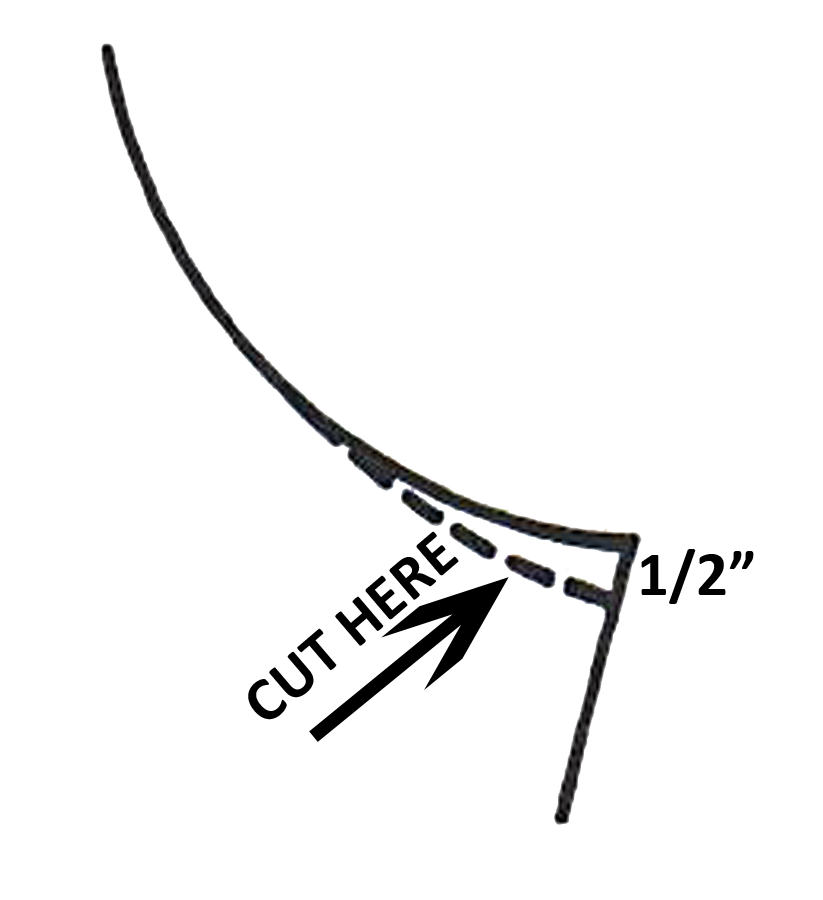

- Open out one seam allowance and pin the binding to the edge of the garment, right sides together. It is important to remember that the other seam allowance always stays folded to the inside of the strip. Position the binding so that you begin stitching at a point that will be hidden in a seam or hem. Stop stitching near the corner, at a point from the intersecting edge that equals the width of the seam allowance.

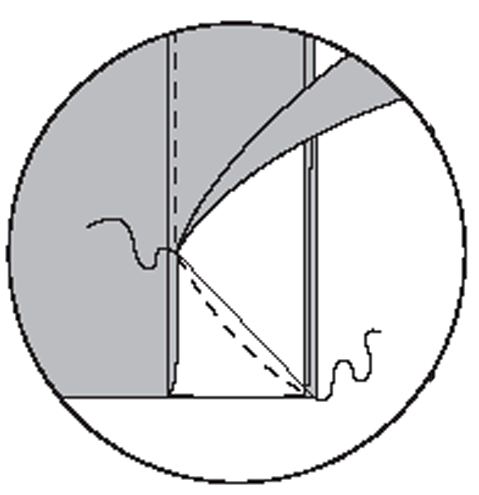

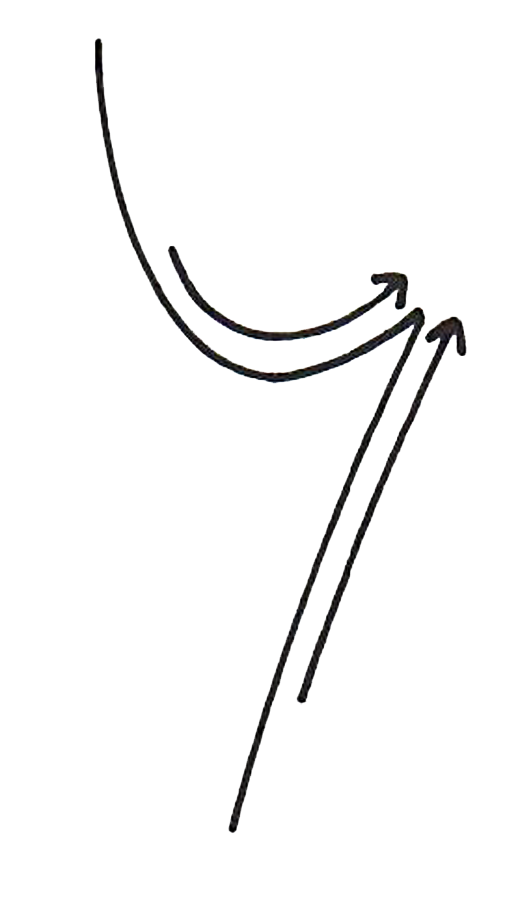

- Fold the binding diagonally against the last stitch, forming an “L.” Place a pin on the binding that matches the cut edge of the garment.

- Using the pin as a guide, fold the binding back on itself. Insert the needle exactly where the previous stitching ended and stitch along the intersecting edge.

Sewing Tip: It will be easier to accomplish this if you turn your garment over and sew on the underside so you can see exactly where the previous stitching ended.

- To complete the miter: using a marking tool, draw an arrow on the binding that starts at the last stitch in the corner, angles out to the center of the binding at the crosswise fold and continues up to a point that meets the seamline.

- Stitch on the marked line, stitching through the binding only; do not stitch through the encased seam allowances. Check that the corner turns and miters well, and then trim the excess fabric. Once the corner is turned, pin the binding to just cover the stitching line and slipstitch in place.

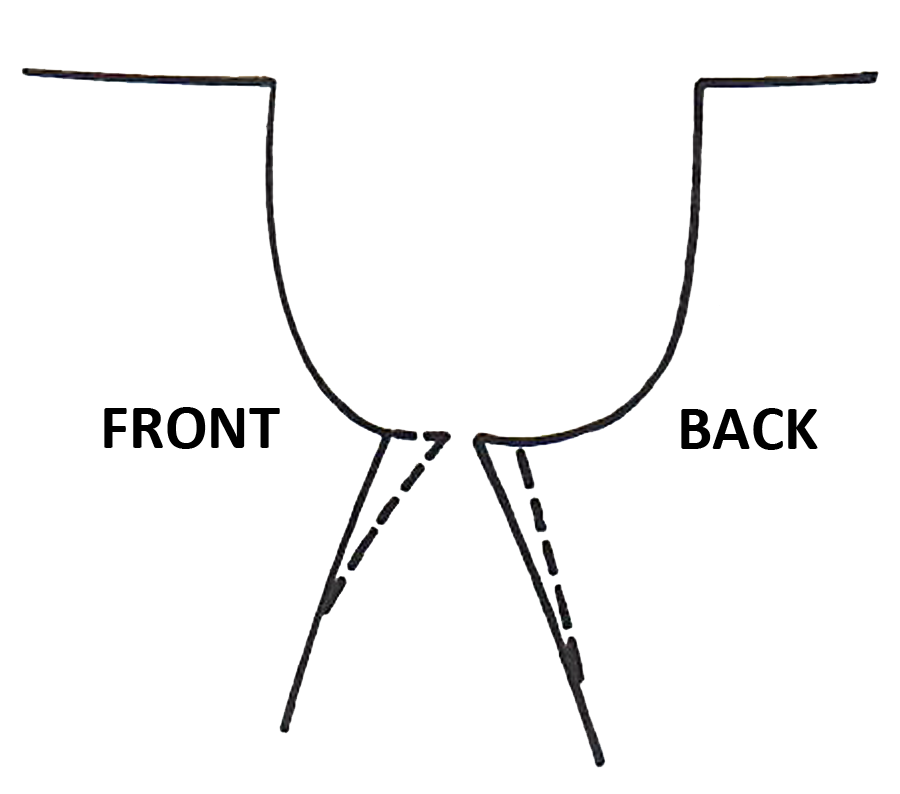

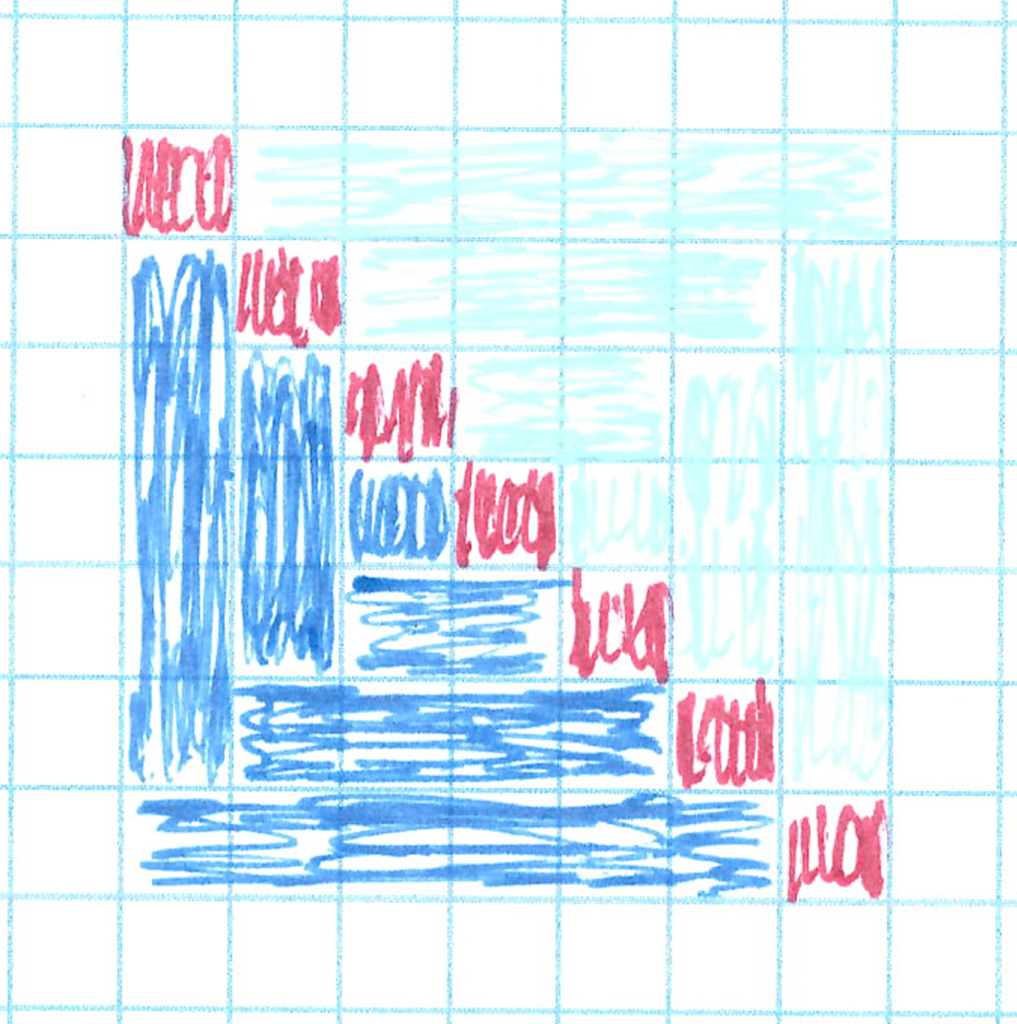

Mitered Hems to the Outside

When a facing meets a hem, there is an opportunity for a miter. Usually, we relegate these connections to the insides of our garment. However, if your fabric has a usable wrong side, rethink this detail. If you turn both edges to the outside, the result is a wonderful couture detail. Increase or decrease the widths of the facings and hems; make them the same width or make them different.

When a garment is lined with contrasting fabric, mitering the hems to the outside brings that contrast color to the forefront. No matter what effect you choose, here’s how to miter the corners perfectly.

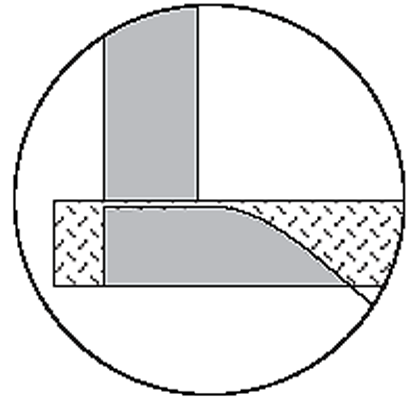

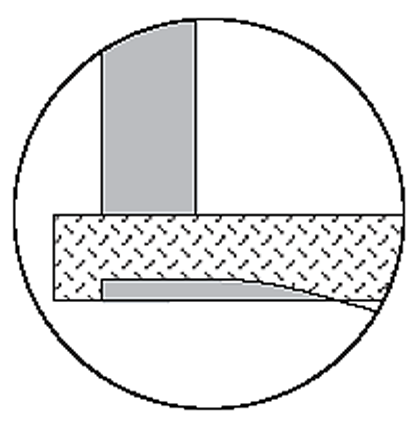

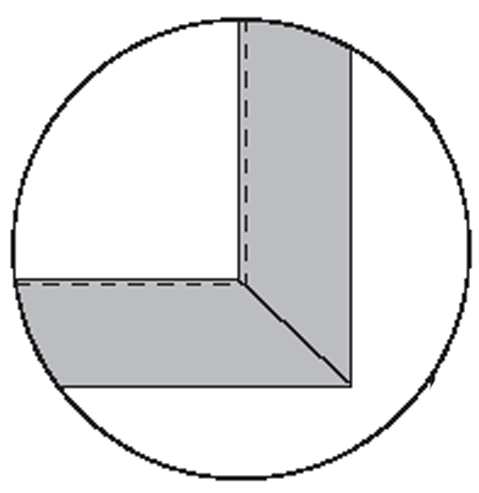

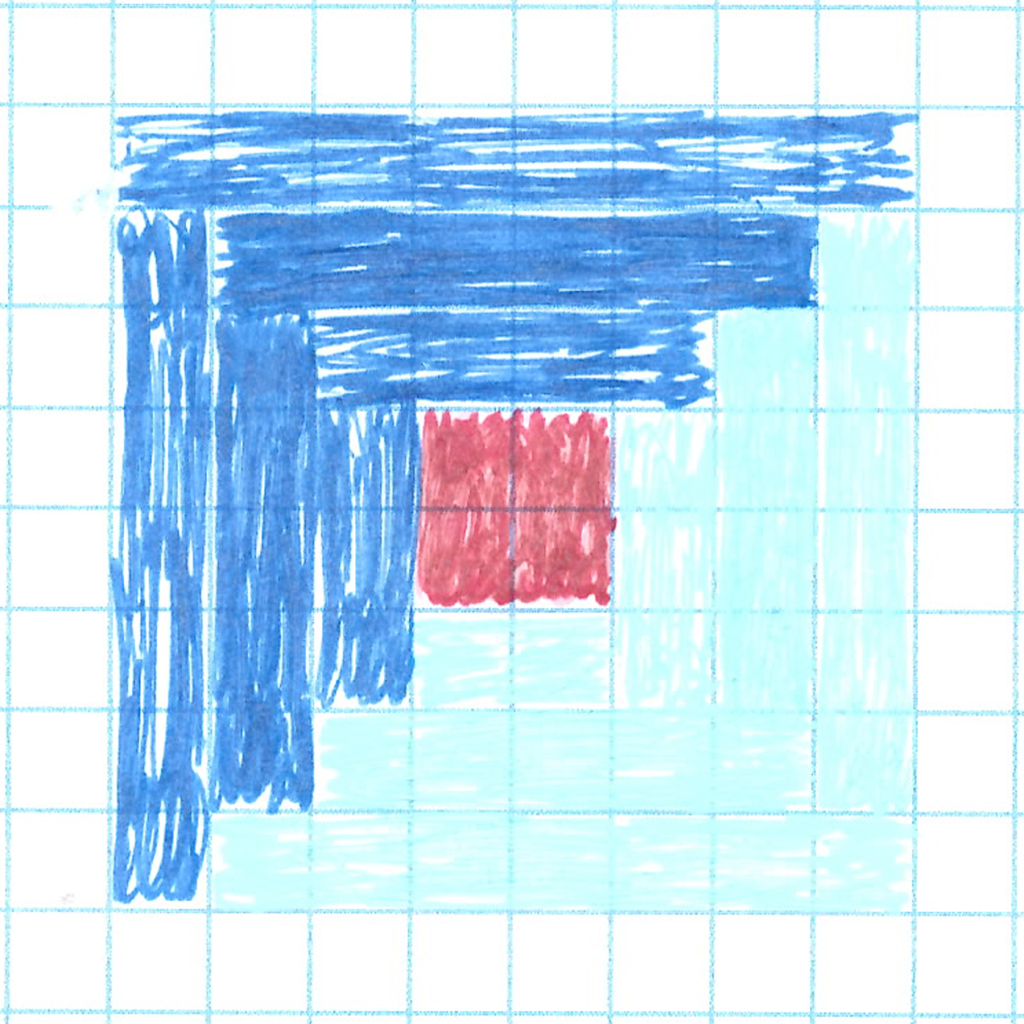

- From a manila file folder, straight-cut two tagboard templates. Cut one template the width of the finished hem or facing and the second template 1⁄2″ narrower than the finished hem.

- Working at your ironing surface, place the widest template on the right side of the fabric. Press the fabric up over the edge of the tagboard, matching the raw edge of the fabric to the top edge of the template. Press through all layers.

- Open out the fabric. Place the narrower template in the pressed crease. Fold the raw edge of the garment up over the template to create a 1/2″ turndown and press. Once you have completed both steps on one edge, repeat these steps to press the intersecting edge. Refold the edges and press both hems in place.

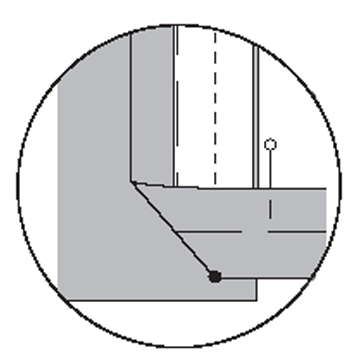

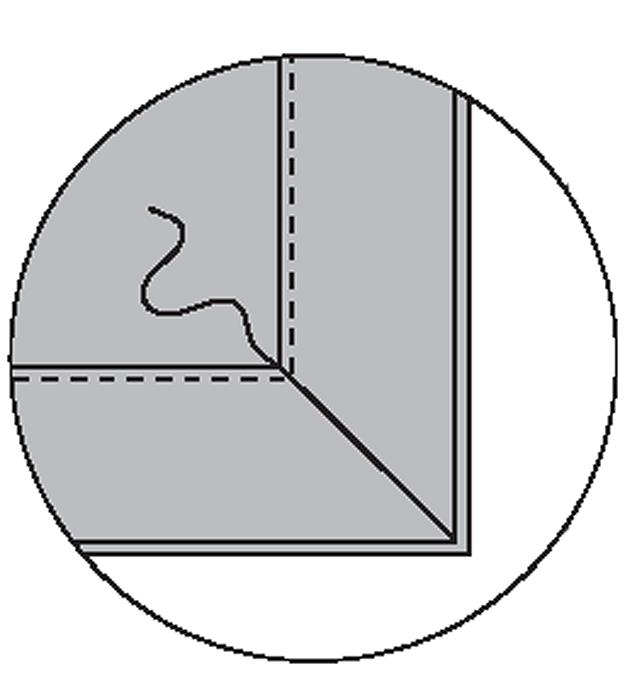

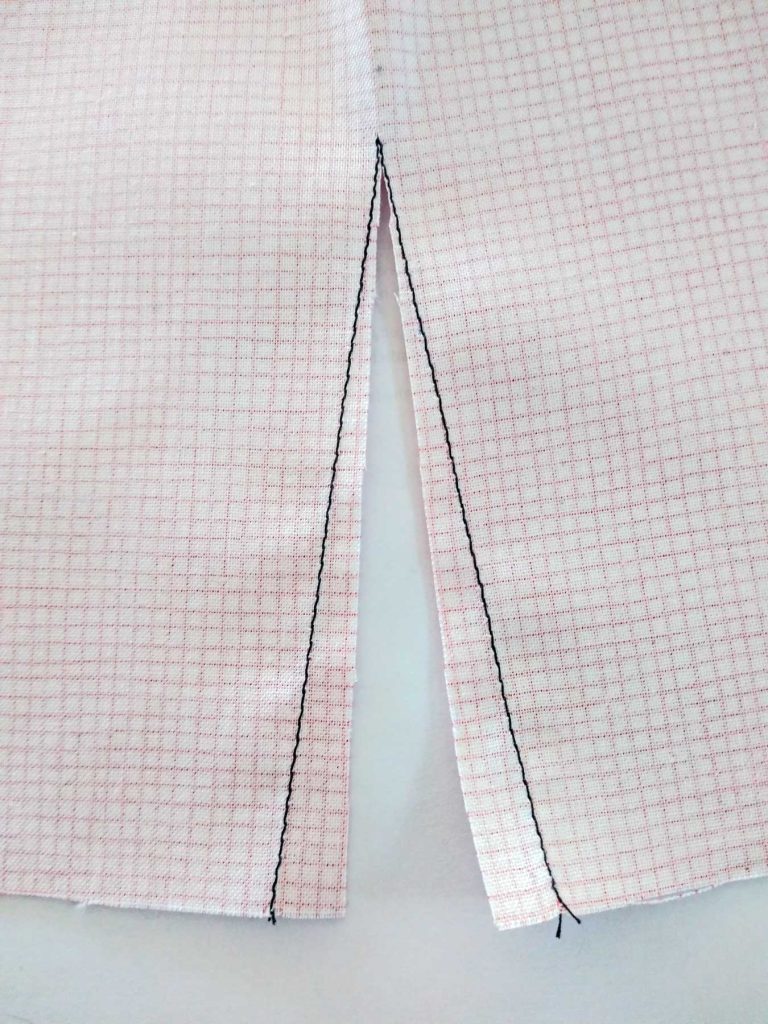

- To complete the miter: Place one pin in the hem allowance only, perpendicular to the hem fold. Place a second pin in the opposite hem fold at the intersection of the two hems.

- Open out the two hems, keeping the 1⁄2″ turndown in place. With the right sides together, match the pins exactly at the folded edges. Mark a diagonal line from the pins to the point where the first creaseline meets the diagonal fold. Sew from the pins to the point, backstitching at both ends. Trim to 1/4″.

- Press the seam open over a point presser. Turn it right side out and press again.

- To ensure a good topstitching line without the hem pulling and rippling, take the time to hand baste along the inner fold. Then it is easy to topstitch the mitered hems in place without any worries.

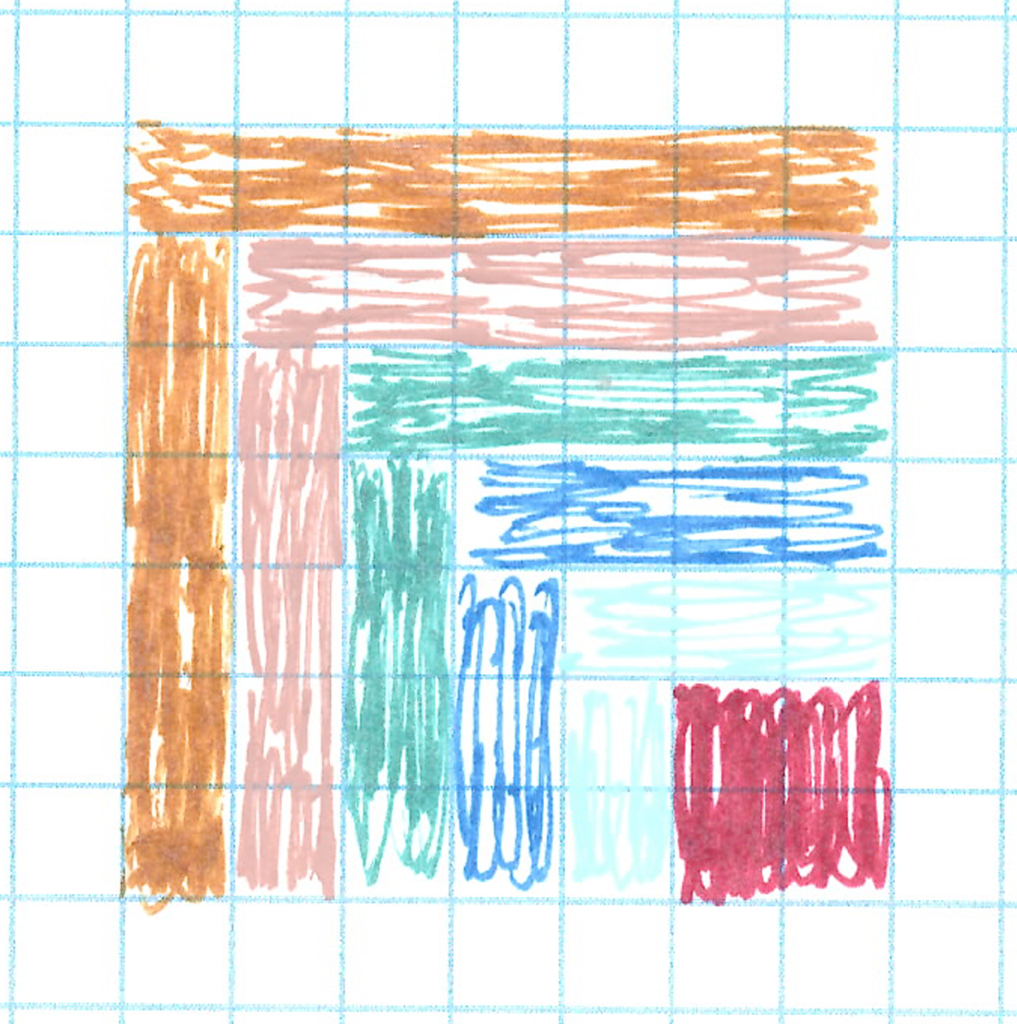

Applied and Mitered Trim

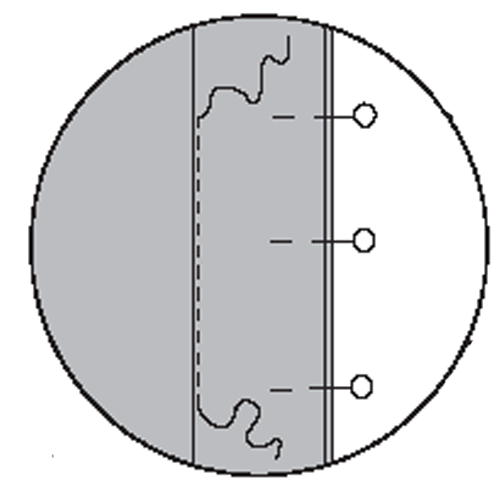

When an applied trim is used to define the edges of a garment, the result is an intriguing design element. Strips of torn fabric, interesting selvages, or ribbons and braids add that adventurous touch to an edge. On an unlined garment, trim can also serve a functional purpose: turn the facing or hem edge to the outside, apply the trim over the raw edge, and you have a clean finish both inside and out.

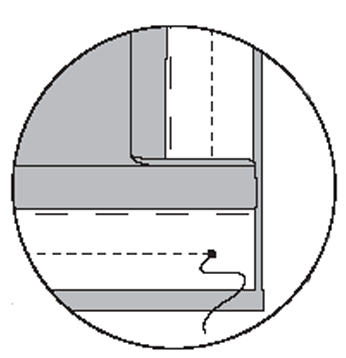

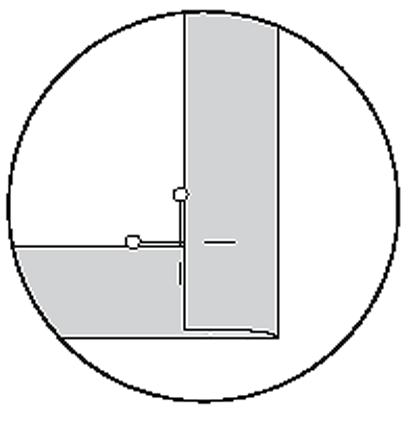

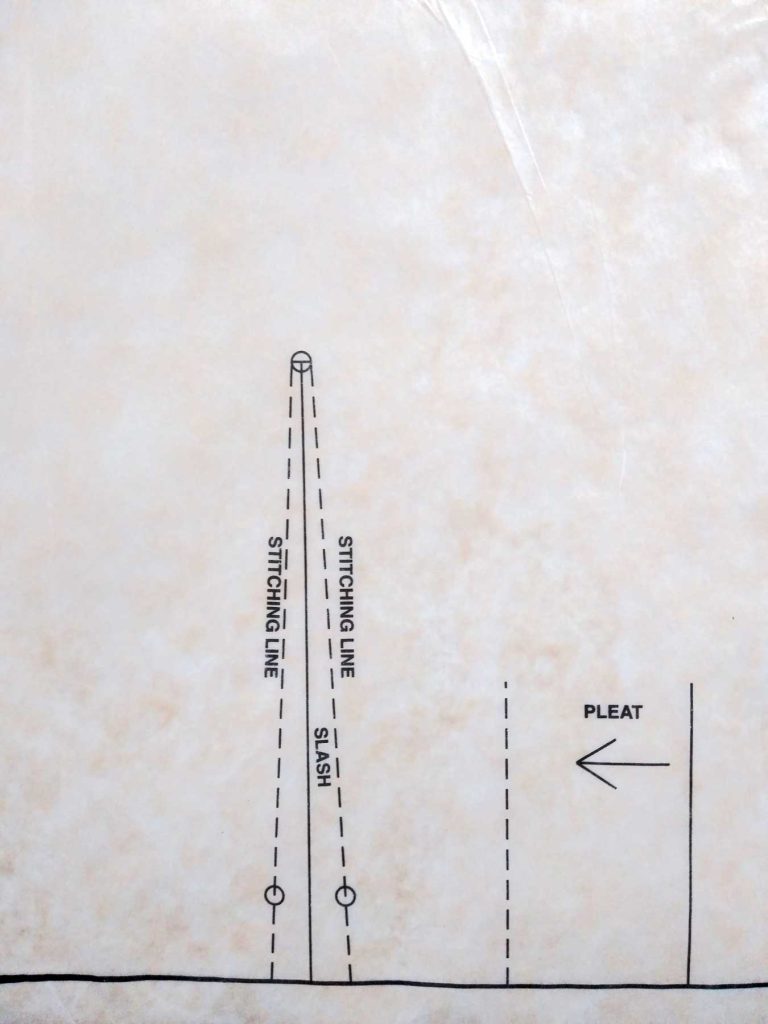

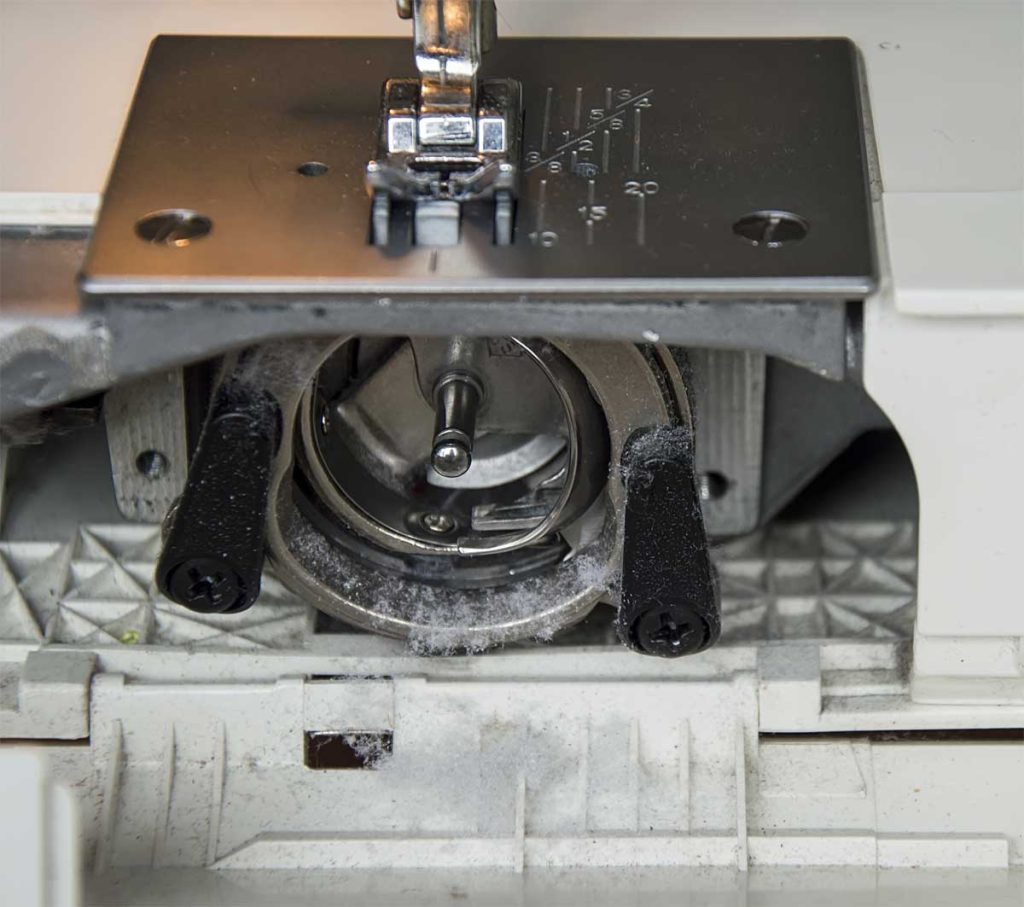

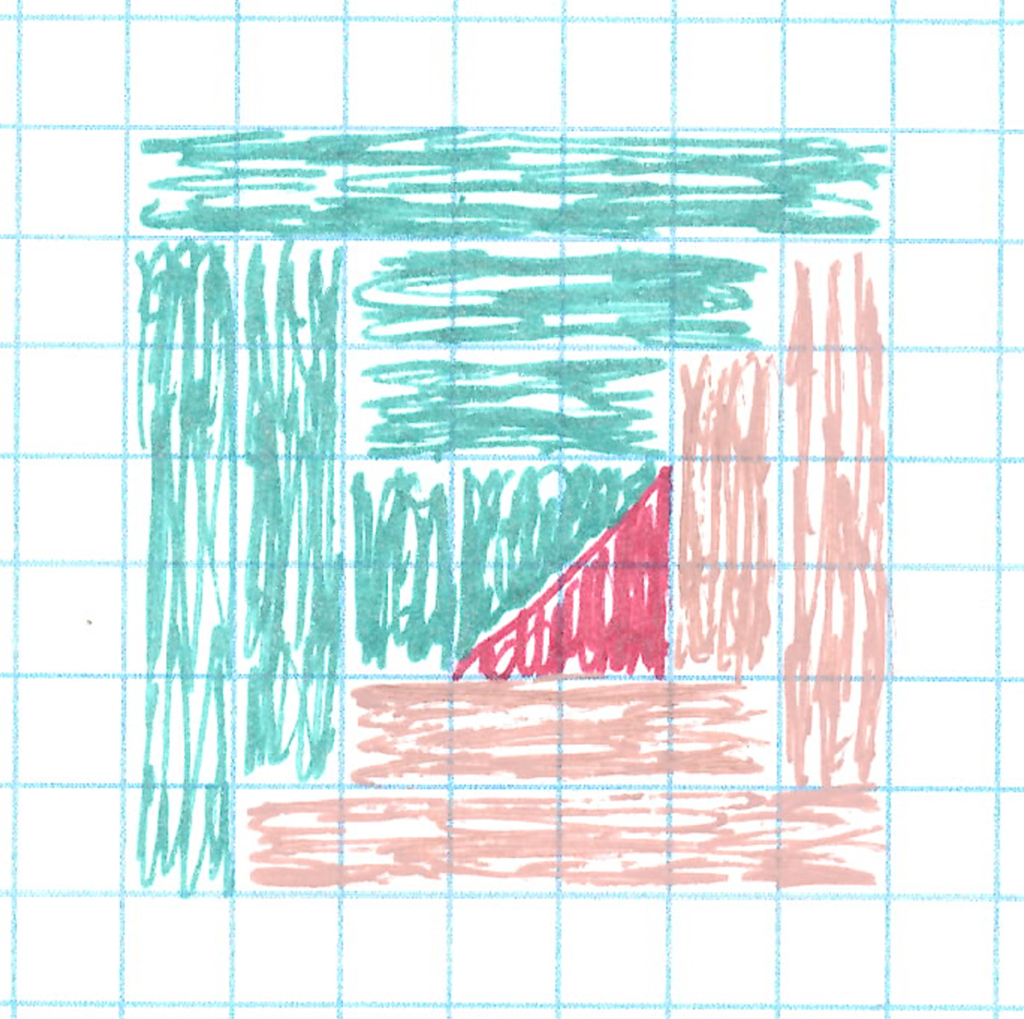

- Cut a length of trim long enough to border the entire garment plus a few inches. Starting at the top of an edge that will be sewn into a seam or hem, pin the trim in place and edge-stitch along its inner edge, stopping at a point above the intersecting edge that is equal to the width of the trim.

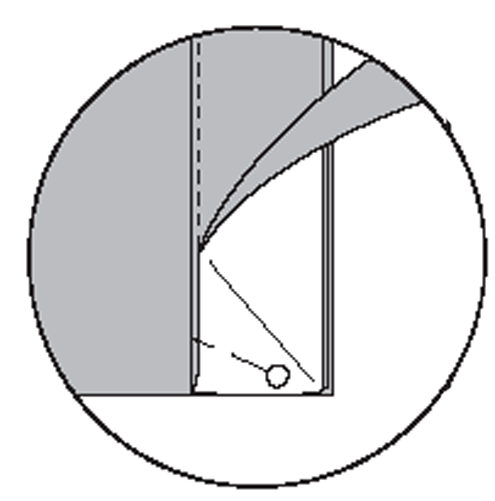

- To complete the miter: At the corner, fold the trim back on itself, aligning the fold with the bottom edge of the garment. Mark a diagonal line from the last stitch on the inner edge to the corner point of the trim.

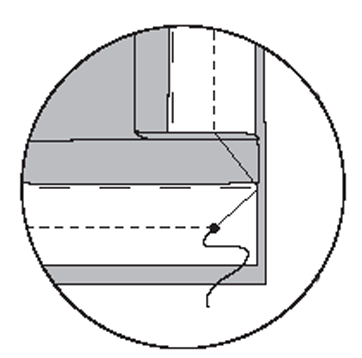

- Using the marked line as a guide, stitch a line with about a 1⁄16″ bow to it through all layers. Trim off the excess below this stitching as best you can. Fold the trim down and continue sewing the inner edge of the trim.

- When all the miters have been done, go back and stitch the outside edge of the trim to the garment. You can sew decorative stitches over the previous straight stitches or couch over small cords or decorative threads to enhance the trims even more.

Linda Lee, ASID is a designer, sewing instructor, and author, including a book titled, “Mastering Miters” (the source of this article’s technical art), and produces The Sewing Workshop Pattern Collection, a group of patterns for distinctive garments using innovative sewing techniques. She is also a licensed interior designer. Learn more at www.sewingworkshop.com.