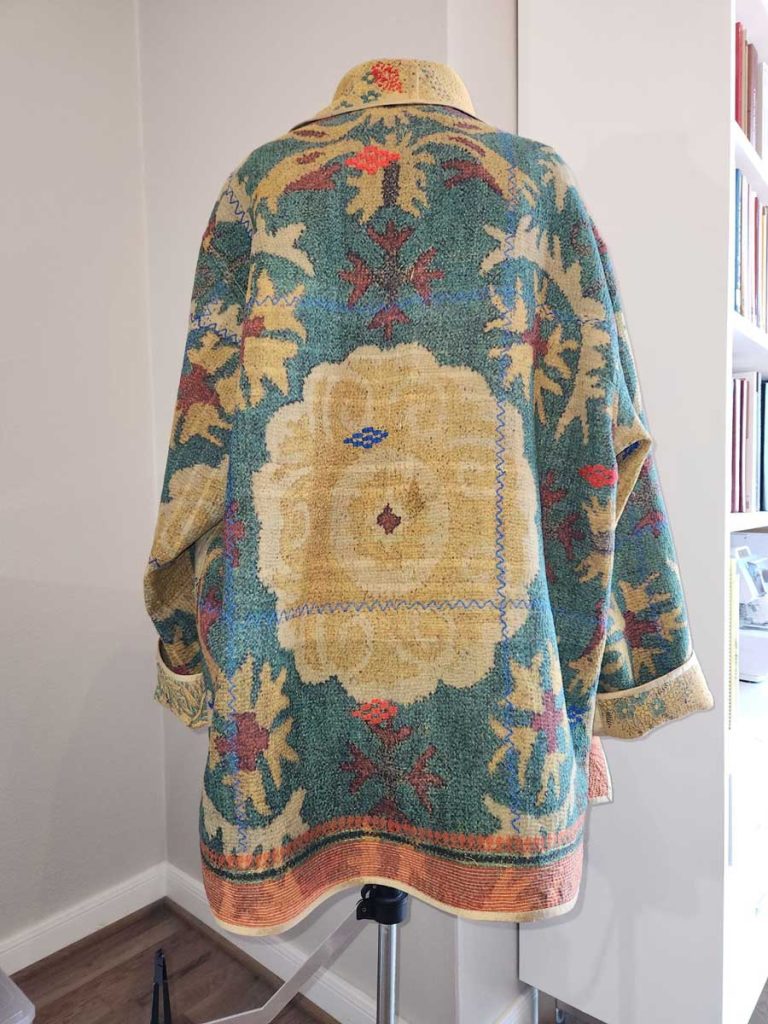

Acid-washed and stone-washed denim are stepping boldly back into the spotlight for 2025–2026, blending nostalgic edge with modern refinement. Designers are leaning into these retro textures to add depth, character, and a lived-in authenticity to jackets, jeans, skirts, and even accessories. This time around, the washes are more intentional—think controlled contrasts, sustainable finishing techniques, and elevated silhouettes that make distressed denim feel fresh rather than throwback. Whether paired with minimalist basics or layered into maximalist looks, acid and stone washes are proving they can move seamlessly from vintage-inspired streetwear to polished, contemporary style.

Stone-washing and acid-washing are two classic ways to give denim that lived-in, high-contrast look. Stone-washed denim is softened and faded by abrasion; acid (bleach) washing uses a controlled bleaching action to create splotchy, cloud-like highlights. We cover some beginner-friendly home methods, safety notes, and a few deeper resources and videos to watch before you start.

Start by pre-washing your denim fabric to remove finishes.

What you’ll need (basic)

- Your denim fabric (100% cotton denim reacts best).

- Household bleach (for acid/bleach wash) OR pumice/polishing stones (for stone wash).

- Large plastic tub or old bucket, spray bottle or squeeze bottle, rubber gloves, eye protection, and an apron or old clothes.

- Neutralizer: hydrogen peroxide or a long rinse and diluted vinegar solution. Always have plenty of water for rinsing.

Acid / bleach (aka “cloud” or acid-wash) — quick method

Work outside or in a very well-ventilated area. Put on gloves and eye protection. Never mix bleach with ammonia or other cleaners.

Dilute bleach with water. A common starting ratio is 1:1 to 1:3 bleach to water in a spray bottle. For gentler results, use more water. Test on a small end area first.

For a clouded look: scrunch and secure parts of the denim with rubber bands or twist the garment to create areas that resist the bleach. Spray or dab bleach onto raised areas — the more you spray, the lighter the area. For sharper, high-contrast speckles, sprinkle bleach with a sponge or pour small amounts.

Watch the color change (this can take from a minute to 20 minutes). When you reach the desired lightness, neutralize the bleach (rinse thoroughly, then soak in a hydrogen peroxide solution or wash with plenty of water) or neutralize with baking soda solution to stop the chemical action. Launder and dry the fabric afterwards.

- View this article from Clorox on How to Fade Jeans with Bleach

Tips for control & creativity

- If you’d like to do specific patterns, use gel bleach or thickened bleach. This will give you more control on jackets and targeted areas; apply with a brush and avoid running. See the step-by-step for a controlled jacket technique offered by Levi’s

- For patterned effects use stencils, rubber bands (reverse tie-dye), or spray bottles to vary coverage. Many tutorial videos demonstrate spraying and banding methods for “cloud” or “acid” textures.

- For random, blotchy effects, you can also soak pumice stones in a bleach solution and tumble briefly with the garment (factory acid wash used a similar concept).

Safety & fabric care

- Bleach is corrosive — use gloves, respirator or mask if sensitivity is an issue, and always wear eye protection. Work outdoors or with strong ventilation. Do not mix bleach with other cleaners (especially ammonia). Neutralize and rinse thoroughly before machine drying.

- Expect some weakening of fibers: both bleach and stone abrasion can reduce fabric tensile strength. Consider reinforcing high-stress areas (crotch, seams) if you plan to wear the piece heavily.

- If you prefer to avoid bleach, try enzyme washes or commercial fading agents designed for home use — they’re gentler on fibers and colors.

Stone-washing (abrasion)

Stone washing uses physical abrasion to rub the indigo dye off the surface of denim, softening the fabric and producing a uniform faded or worn look that has some vintage appeal.

- Stone-washing at home mimics industrial processes by rubbing stones or pumice against the fabric.

- Use commercial pumice or ceramic stones (available online) and a large, sturdy tub or old washing machine set to a gentle cycle. Important note: Do not use your good washing machine for this!

- For pumice, soak the denim in salt water overnight, then wring out the excess water. Spread the fabric on a flat surface, smoothing out all the wrinkles, then rub with the pumice stone or sandpaper until areas of white fabric appear. Make sure you don’t rub too long in one spot that you cause a hole. Fill a bucket halfway with water, then add a cup of salt and properly dissolve it.

- For true stone washing, set your (old) washing machine water level to low and the water temperature to hot and add 1/4 – 1/2 cup of detergent, then add 3 cups of non-chlorine bleach. If your denim is 100% cotton, you can use 1 1/2 cups of chlorine bleach. Add stones and allow the machine to agitate for a few minutes before adding the fabric. When the wash cycle is complete, remove the fabric.

- This process is abrasive — it will thin the fabric over time, so don’t overdo it. Repeat until you reach the desired fade. Do a final rinse and then tumble dry.

With experimentation and attention to safety, you can create beautiful stone- or acid-washed effects that refresh thrifted denim or breathe new life into a jacket. Try small tests first, vary spray concentration and tumble times, and keep notes — that way you’ll quickly learn what produces the exact fade and pattern you love. Happy distressing (safely)!

Need more denim info? Try this articles.