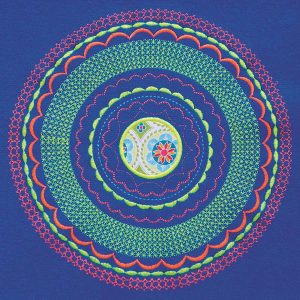

In everyday life, the phrase “going in circles” doesn’t necessarily have a positive connotation, but for creative sewers going in circles can be loads of fun! Those decorative and utility machine stitches are ideal for circular sewing, and there’s an attachment made just for that. But never fear, if your machine doesn’t have an available attachment, you can still do it.

Attachments

Many machine brands offer a circular sewing attachment—a calibrated slider with a vertical pin to mark the circle center.

The attachment screws to the base of the machine and the sliding rule adjusts the circle radius to the size needed for circular sewing. Depending on the brand, you may be able to stitch up to a 15”-diameter circle.

Remember high school geometry? The radius of the circle is one-half its diameter (the distance across the widest point).

Stitching

The fabric you’re embellishing needs to be stabilized for stitching, so choose a stabilizer that suits the fabric. Though a hoop isn’t required for circular stitching, it’s helpful and it can hold temporary stabilizer in place. Add an extra bit of stabilizer at the circle center as it will be secured to the center pin and no wobbling is a must.

Select a stitch of choice—anything from straight to the wildest decorative varieties. One note of caution—because you’re stitching in a circle, the joining point stitches may not be exactly matching, so perhaps make a plan to cover them if needed with something like beads, buttons, tassels, etc. Creating overlapping circles is one way to solve this. If you stitch partial circles, or arcs, this isn’t an issue as there are no joinings.

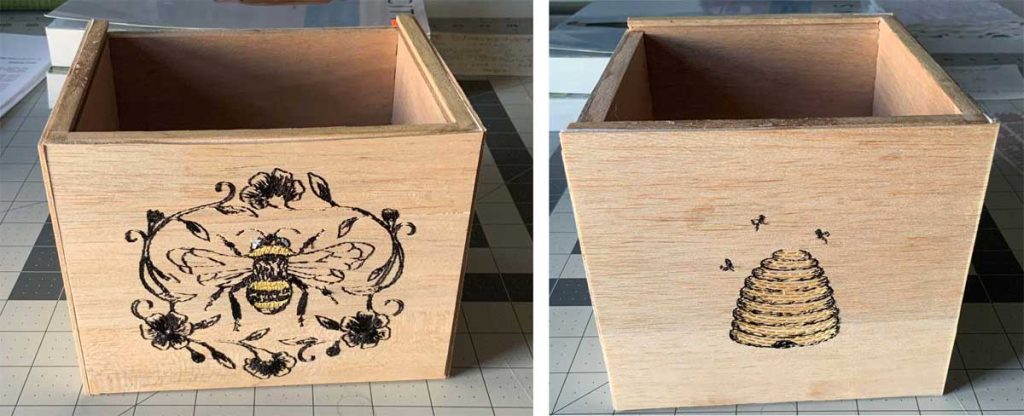

Sewn circles can be used to embellish all kinds of projects from totes to garment sections and also trimmed for craftier applications like coasters or mats. Circles can be used alone or combined with machine embroidery motifs to make beautiful medallions.

Circles can also be combined with appliqués.

If stitching arcs, the stitched rows can end in a seam for security, or all threads can be pulled to the back at the end of stitching line and tied off to anchor.

The circle attachment can be used with almost any foot you have for the machine, and with any needle type, including double and triple needles. Use it with regular, embroidery or novelty threads.

Making it Happen

It’s best to start your project with a full bobbin, as some attachments limit access to the bobbin area. And, for best visibility, use an open-toe or clear foot for stitching.

If your machine isn’t in a cabinet, use an extension table to create a large flat area so the fabric doesn’t drag while stitching.

Follow the manufacturer’s instructions for attaching the circle stitcher to the machine. Adjust the slider so that the center pin is the desired radius distance from the needle and tighten in place as directed. With right sides up, push the fabric circle center down onto the pin, then place the safety top in place to hold the fabric firmly in place. The fabric should be able to pivot easily on the pin.

Leave a long thread tail to allow for tying and begin stitching. Keep the fabric flat while you sew the circle, and don’t push or pull—just let the machine feed the fabric to form the circle. Stop the stitching at the exact beginning point of the stitching, pull threads to the back and tie off to secure. To stitch concentric rows, begin in the middle and work outward. Move the slider to the desired spacing between rows and retighten. Do not take the fabric off the center pin until all concentric circles are complete.

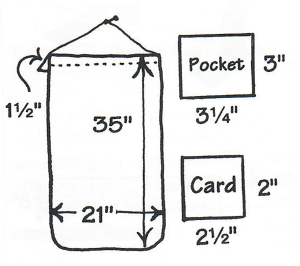

DIY Circle Sewing

If you don’t have a circle stitcher attachment, use a thumbtack with a flat head and tape it securely to your machine base with the point up. The distance from the needle to the tack point will be the circle radius. Position the fabric as noted for the attachment and secure it in place with a firm pencil eraser placed over the tack to allow the fabric to pivot freely.

~Linda Griepentrog is the owner of G Wiz Creative Services and she does writing, editing and designing for companies in the sewing, crafting and quilting industries. In addition, she escorts fabric shopping tours to Hong Kong. She lives at the Oregon Coast with her husband Keith, and three dogs, Yohnuh, Abby, and Lizzie. Contact her at .

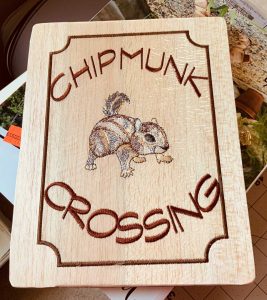

Each penetration of the needle creates a hole in the wood that does not heal so it is best to use the smallest needle that can get the job done. The samples shown here were all stitched with a 75/11 universal needle. The needle will dull more quickly than normal stitching through fabric, so be sure to change it frequently and make sure to keep any that you use designated for wood. My needle did over 100,000 stitches and was still going strong! It is also a good idea to stitch at a slower speed — setting the machine at 600 stitches per minute should be fine in most cases. Begin each design by lowering the needle into the wood, then starting the stitch out. This small trick seems to anchor the wood to the stabilizer and helps reduce the impact of that first stitch, thus avoiding broken needles.

Each penetration of the needle creates a hole in the wood that does not heal so it is best to use the smallest needle that can get the job done. The samples shown here were all stitched with a 75/11 universal needle. The needle will dull more quickly than normal stitching through fabric, so be sure to change it frequently and make sure to keep any that you use designated for wood. My needle did over 100,000 stitches and was still going strong! It is also a good idea to stitch at a slower speed — setting the machine at 600 stitches per minute should be fine in most cases. Begin each design by lowering the needle into the wood, then starting the stitch out. This small trick seems to anchor the wood to the stabilizer and helps reduce the impact of that first stitch, thus avoiding broken needles.