What is the selvage?

Selvages are the edges of woven fabrics—the place where the weft (crosswise) threads turn around to form the next row during the weaving process. Some selvages are thicker than the fabric itself, as often there are more threads per inch at the edges to help keep the edges straight during the weaving process.

Selvages may be the same color as the fabric, or they may be a contrast. Interestingly, contrast threads are sometimes woven in the selvages. On some velvets and velveteens, you may see metallic threads along the edges.

On high quality and imported fabrics, sometimes the requisite information like fiber content and country of origin is actually woven into the selvage in a contrasting thread color.

Selvages are not always straight—they can be fringed or looped, depending on the type of loom used and the finishing processes.

Selvages are not always straight—they can be fringed or looped, depending on the type of loom used and the finishing processes.

On fabric like denim where the warp (lengthwise) threads are a different color than the crosswise threads, the selvages may be totally different looking than the fabric body itself.

Information, please

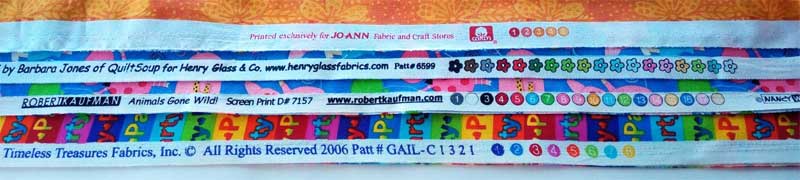

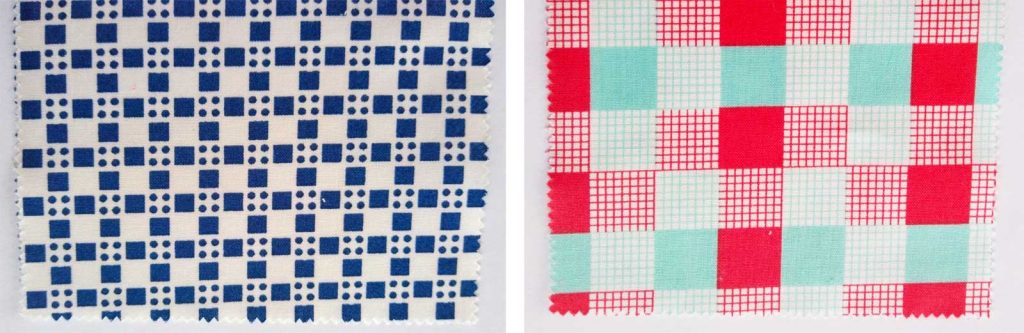

You can find a variety of information bits on most selvages, but some have none. Look for the brand name, the designer’s name and sometimes the fiber content and/or care instructions, like “dry clean only.” You may also find the date the fabric design was copyrighted, and on printed fabrics, you may see lots of colored dots or shapes along the edge. These fun indicators tell how many different color screens were used in the printing process of the particular fabric.

- Some selvage edges include the website for the fabric brand or a social media reference. Designers have even been know to add an inspirational message on the selvage.

- In addition, home décor fabrics may show an indication of the repeat of the pattern, and sometimes an arrow showing which direction is up in the patterning.

Saving Selvages

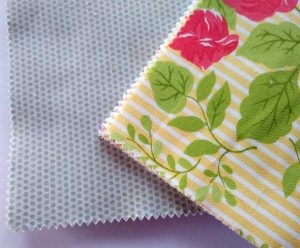

Because of their tighter weave, the selvages may shrink differently from the fabric itself, so many people just cut the selvages off before cutting out the project.

While you can certainly trim and toss them, you can also use them creatively. If your project has a straight seam edge, you can cut it on the selvage to avoid raveling and perhaps add a decorative touch to the seam edge. A pant leg seam or a loose fitting, straight-cut jacket would be two great places to cut on the selvage for pre-finished seam allowances. Selvages are also a great edge for pockets or straight hems, either exposed for interest, or just as an edge finish.

Trimmed selvages are often used to stabilize a stretchy area—like a shoulder seam in a knit T-shirt. Lightweight woven selvages, like silk organza, are ideal for this use, as they’re sheer and don’t add a lot of bulk as they span the seamline. Interesting cut-off selvages can also be “reapplied” to an area as a decorative trim, often combined with ribbons, braids or decorative stitching. Fun selvages are also great to insert as a flat piping.

Selvages (with some attached fabric width) can also be used for bindings or garment ties.

Quilting Ideas

If you’re a quilter, perhaps you keep all your cotton selvages for other projects. It’s easy to strip piece them together on a lightweight backing to make quilt blocks or other projects. When you trim the selvage, leave at least ¼” beyond the actual selvage and use that for joining. Layer the strips one edge over the other and zigzag the edges in place through the backing until you fill the space needed.

Crafting Ideas

For crafting, trimmed selvages are ideal for decoupaging onto projects—like basic tennies {photo}, picture frames, boxes, vases, etc. Just overlap the raw edge portion and seal with the medium.

Holey Moley

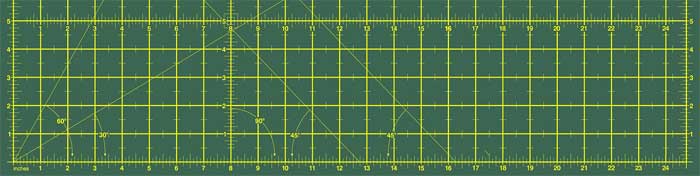

What are those holes along the selvage? They’re called tenter holes and they’re used to hold the fabric to a frame during the printing and finishing processes.

~Linda Griepentrog

Linda is the owner of G Wiz Creative Services and she does writing, editing and designing for companies in the sewing, crafting and quilting industries. In addition, she escorts fabric shopping tours to Hong Kong. She lives at the Oregon Coast with her husband Keith, and two dogs, Yohnuh and Abby. Contact her at .

If the idea of sewing with leather didn’t scare you off, you may be adventurous enough to try sewing on wood. No, you probably won’t be making a dress or a pair of pants from wood, but it can be used to make interesting accents, ornaments, box tops, home decor pieces, etc. And it certainly will be intriguing to show off at your next Neighborhood Group show-and-tell!

If the idea of sewing with leather didn’t scare you off, you may be adventurous enough to try sewing on wood. No, you probably won’t be making a dress or a pair of pants from wood, but it can be used to make interesting accents, ornaments, box tops, home decor pieces, etc. And it certainly will be intriguing to show off at your next Neighborhood Group show-and-tell!