There’s nothing quite as elegant as a knotted button and loop closure. This traditional Chinese knot has been used for centuries, and you can custom make them to coordinate with special garments. In addition to being used as a functional closure, these interwoven balls of cord can be used for necklaces, earrings and other types of embellishment as well.

Getting started

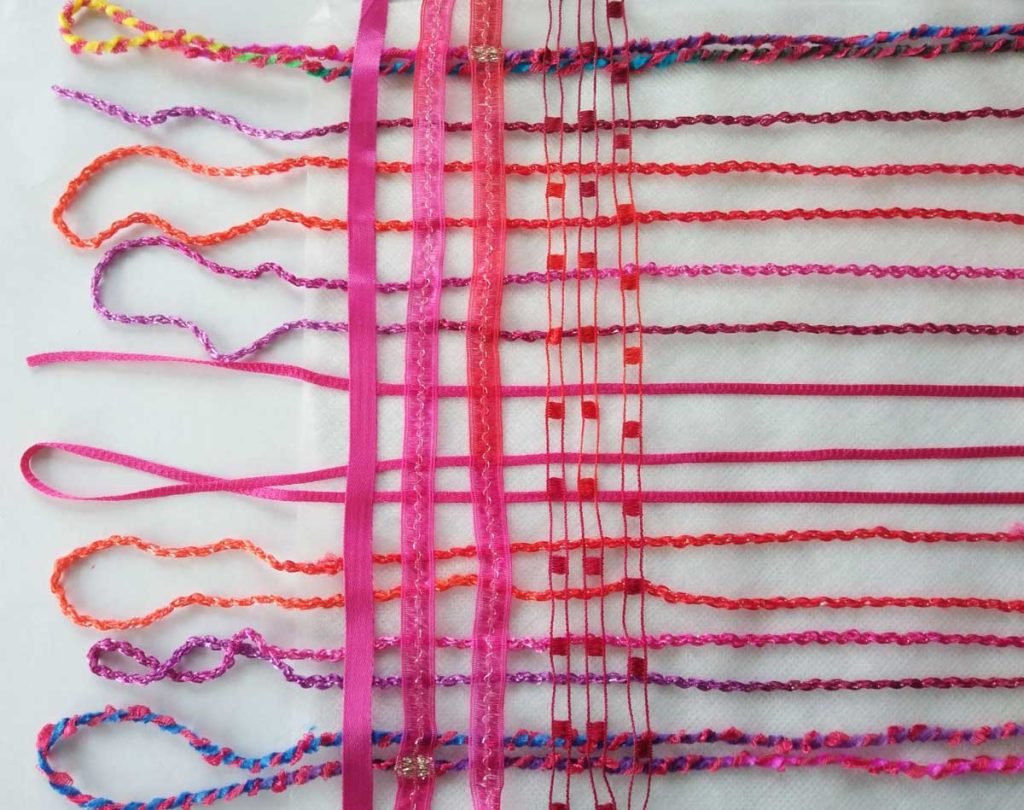

To get started, choose a ready-made cord about ¼” diameter. Satin cord works well, as does woven rayon or metallic. Note that if the cord has a filler (light padding), it makes a more attractive ball. Velvet cord can also be used to create slightly larger balls. You’ll need 12”-18” per button, depending on the thickness.

If you’re using the ball button for a home décor use, you can use cable cord or a larger tubular cord to make a much bigger button than you would for a garment closure. You can also use rope for a nautical look. Chinese knot buttons are great for incorporating into drapery tie-backs or as elegant slipcover closures.

Another option is to make your own fabric tubing. To do this, cut a length of bias fabric (silk is ideal) 1 ½” wide. Fold the cord in half right sides together—matching raw edges—and add a narrow strip of lightweight batting under the folded fabric. Stitch along the cord length using a ¼” seam, catching the batting in the stitching. Use your favorite turning tool to turn the stuffed cord right side out and then smooth into shape.

In addition to the cord or tubing, you’ll need matching thread, scissors, a hand needle and a fray stopper or fabric glue for finishing the cord ends.

Ready, set, weave

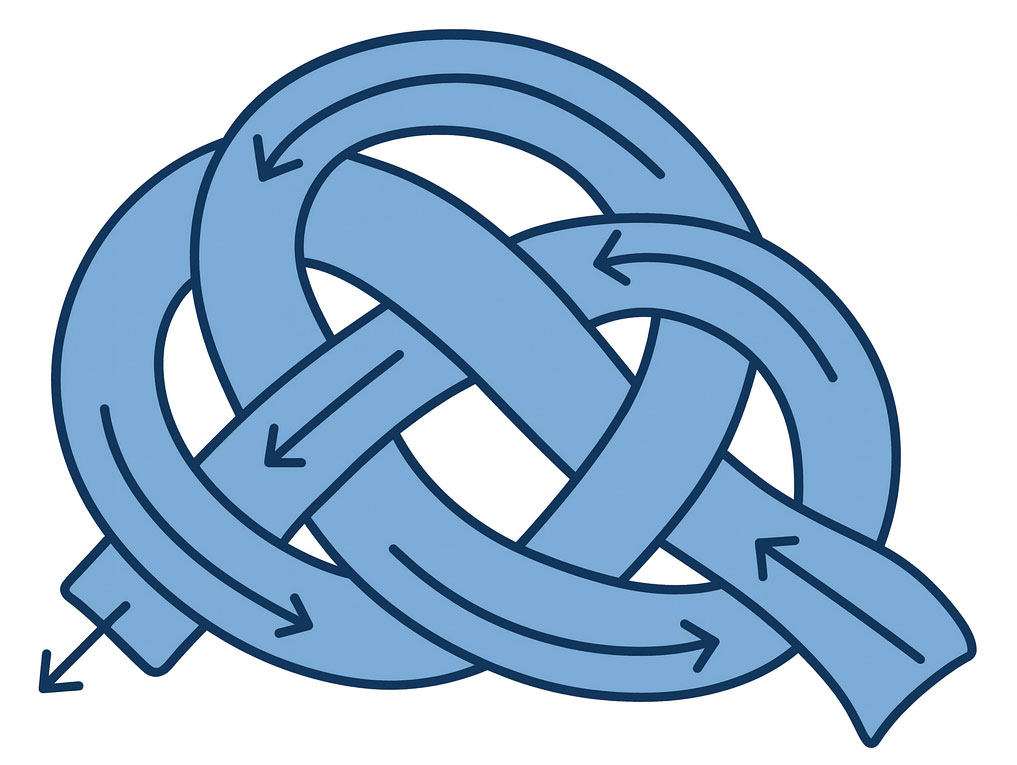

- Begin by folding the cord into a loop with one end OVER the opposite end.

2. Make a second loop behind the first one forming a pretzel shape.

3. Weave the second end of the cord over and under each cord in the pretzel pattern to create a sustainable knot shape. Note that it’s the over/under intertwining pattern that holds the cords together.

4. To shape the knot, gently coax each loop and pull to snug them together. If you pull too fast, the shape of the ball will be wonky.

5. Pull up to get the ball shape or leave looser for a flatter button.

Finishing

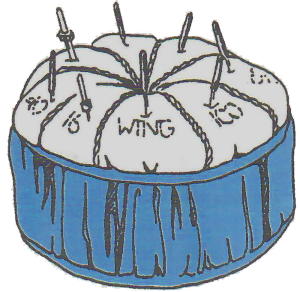

Once you have the button in a pleasing shape, trim the ends of the cording about ¾” from the knot. If the cord or fabric tube ends are ravelly, add a bit of fray preventer or fabric glue to secure them.

Sew the cord ends together and tuck them into the knot underside to secure. Leave the threaded needle attached to sew the button to the project.

Wrap the thread around the thread shank you created in that process to make an attractive finish for the button application.

Use ball buttons with loops on the opposite side of the closure, as they’re too bulky for a traditional buttonhole.

~Linda Griepentrog is the owner of G Wiz Creative Services and she does writing, editing and designing for companies in the sewing, crafting and quilting industries. In addition, she escorts fabric shopping tours to Hong Kong. She lives at the Oregon Coast with her husband Keith, and three dogs, Yohnuh, Abby, and Lizzie. Contact her at gwizdesigns@aol.com.

When I first moved to my small coastal town, I discovered that the post office does not deliver mail to the town’s residents. “What?” But the more I thought about it, there was an opportunity for exercise and walking the mile-and-a-half circuit to the post office with at least one of our dogs, to retrieve the mail. Along the way early on in the adventure, I passed an adult care home and a lady was sitting on the covered porch in her wheelchair calling out “doggie, doggie!” So, I went up to the porch with the dog and we started to chat. I asked her how many people stopped to talk to her, and she replied “no one, but you.”

When I first moved to my small coastal town, I discovered that the post office does not deliver mail to the town’s residents. “What?” But the more I thought about it, there was an opportunity for exercise and walking the mile-and-a-half circuit to the post office with at least one of our dogs, to retrieve the mail. Along the way early on in the adventure, I passed an adult care home and a lady was sitting on the covered porch in her wheelchair calling out “doggie, doggie!” So, I went up to the porch with the dog and we started to chat. I asked her how many people stopped to talk to her, and she replied “no one, but you.”