We all have a stash of projects in drawers, on shelves and in containers that have been started but never quite crossed the finish line. ASG member, Hope Wright, had a stash of UFO’s and a plan and now she’s sharing her tips and hints on how an online challenge in 2011 inspired her to finish an unprecedented 926 projects. (Yes, 926!)

Here’s Hope’s story…

Sort, Sort, Sort

Sort, Sort, Sort

I first started in 2011 during a challenge from an on-line group. Attempting to use only “from my stash,” I first gathered all the projects I had already started in to one place. I then sorted them by estimating how long it would take to finish each project. The first group were projects that would take just an hour to finish. Next came projects that could be done in an evening after work. Finally, projects I could do on a Saturday.

By using this system, I have completed 926 projects to date. I do add projects to my stash, but I try very hard to finish everything I think I can complete in an evening or on a Saturday morning. Longer projects still await!

Organize

Organize your kits, stash and tools in some way that makes sense to you, or at least gather them together so you can find them. For me, I have most of my tools and gadgets in a bookcase in my sewing room.

Try organizing your projects by type of material, where to work, time it will take to complete, color, expense, etc. Group projects that are repetitive. For example, cut out several projects in one session and make your own kits.

Get rid of anything you have no desire or need to finish. Take that group and consider if someone else may want it for their UFO stash. I’ve given several boxes of supplies to a school art program. Remember, it’s also okay to just put it in the trash!

Make Three Lists

Projects to get to this coming year.

Projects to get to this coming year.- Projects, ideas, and stash in storage. This includes actual kits you have and ideas to do “someday” – or as one person said, her Craft Retirement Account.

- Projects completed. It is great to see what you’ve accomplished!

Categorize Active Projects

An important function for me is that I always actively work on 3 projects at any one time, with 3 to 9 more in line so I never have “down” time. Everything else remains stored away; anything more than 12 is simply too overwhelming. My active projects are categorized by where I can do them:

- Something to do at home, but can’t be done in front of the TV (such as using the cutting table or sewing machine). These are often things I do on the weekend rather than after work. Many projects then move to the next category.

- Something I can work on while listening to TV, such as pressing, hand sewing, or embroidery. Some projects then move to the next category.

- Something I can do in a waiting room, meeting, or traveling. These projects are easy to stop at any point, small to pack or carry, do not require extra light, magnification, or a table to spread out. I always have a project in a tote bag with all supplies to be able to work on it. I nearly always keep one in the car.

Projects with Deadlines

I work on anything with a deadline first, even if I have a lot of time. It is much better to finish something six months early than a day late. Between all my clubs and church, I do a dozen or more programs and deadline projects during a year. I put them first on my “to do” list on January 1 and indicate the deadline.

Finally, I also look at promises already made before I agree to do something more. I try to finish Christmas gifts before Thanksgiving week so I can enjoy holiday parties. Since most groups have their programs planned a year at a time, I know I will start working in December on programs for the coming year. I will seldom start anything else until they are done. Find what works for you to take those UFO’s off your radar!

~© Hope Wright, ASG Member

This story is by Hope Wright from ASG Springfield Lincolnland Chapter

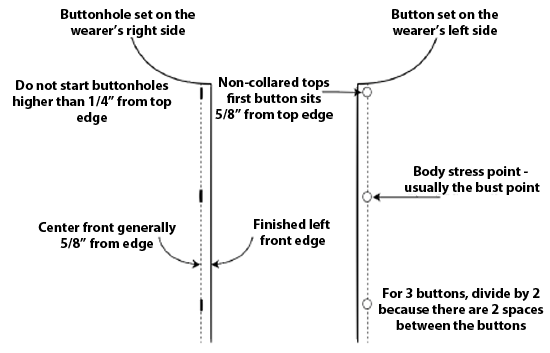

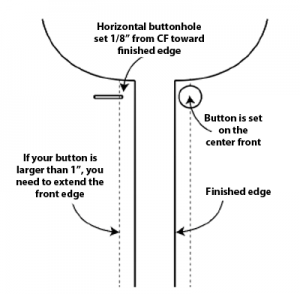

This story is by Hope Wright from ASG Springfield Lincolnland Chapter Button and buttonhole placements can sometimes be confusing. If the button and buttonhole are placed incorrectly, the garment may be too tight, too loose, or create gaping. The number of buttons on the garment is suggested on your pattern envelope, but it’s up to your personal preference or need. A good guide to start placing your buttons vertically is to keep in mind your body’s pressure points. Pressure points are where your body may put strain on the garment and may be your bust, belly, or even the hip if you are making a button front dress or skirt.

Button and buttonhole placements can sometimes be confusing. If the button and buttonhole are placed incorrectly, the garment may be too tight, too loose, or create gaping. The number of buttons on the garment is suggested on your pattern envelope, but it’s up to your personal preference or need. A good guide to start placing your buttons vertically is to keep in mind your body’s pressure points. Pressure points are where your body may put strain on the garment and may be your bust, belly, or even the hip if you are making a button front dress or skirt.