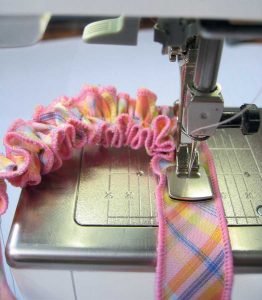

Perhaps you use your serger only for making neatly finished seams—but there’s so many other things you can do with it. One of my favorites is a rolled hem.

Whether you’re creating beautiful edges on napkins or silk scarves, or delicate hems on lingerie, the rolled hem is perfect to hide any “pokies” of thread along the edge. It’s also ideal for quickly finishing ruffle edges.

On a Roll

Used with permission

Before you begin the rolled hemming process, read your instruction manual for setting adjustments. Some brands of sergers utilize a different needle plate, others a separate foot or attachment, but common to all is altering settings so that the fabric edge rolls under. This is usually accomplished by making adjustments to the tension settings and stitch width, and using only one needle.

Narrow rolled hems can be stitched with regular serger thread or a novelty thread, like Woolly Nylon or a texturized polyester that fills in the stitched area. These threads will produce more of a satin stitch look to the edge, covering the entire fabric edge. Using rayon thread in the upper looper will produce an edge with a sheen, while texturized polyester thread creates a matte finished edge.

If your serger has a standard setting for a rolled hem, follow the instructions for its use. If you need to manually adjust, begin by using a narrow stitch finger for a perfect roll. Tighten the lower looper tension so that the fabric edge rolls under and is encased by the upper looper thread. You may need to adjust the needle tension to perfect the stitch. Shorten the stitch length to produce the look you want. It’s all a matter of testing on the fabric you want to hem, as each fabric reacts differently. Softer fabrics roll easier than stiffer fabrics which may not roll at all.

Change it Up

For variation, try using a variegated thread, but note that you might produce a striped edge depending on the thread brand, as some threads are dyed in regular intervals, while others are dyed randomly.

In addition to creating a lovely edge finish, a narrow rolled hem can also be used to stitch a seam in delicate fabrics like lingerie tricot or sheers. Only the width of the stitch shows, creating an almost invisible seamline. To use as a seam, leave the stitch length slightly longer than for edge finishes to keep the seam soft and subtle.

~Linda Griepentrog

Linda is the owner of G Wiz Creative Services and she does writing, editing and designing for companies in the sewing, crafting and quilting industries. In addition, she escorts fabric shopping tours to Hong Kong. She lives at the Oregon Coast with her husband Keith, and two dogs, Yohnuh and Abby. Contact her at .

Napped fabrics are normally cut so that the nap runs down the garment, from the top down toward the lower hem. This feels softer, and the fabric tends to pill less and wear better. However, when the nap runs up, the color is richer.

Napped fabrics are normally cut so that the nap runs down the garment, from the top down toward the lower hem. This feels softer, and the fabric tends to pill less and wear better. However, when the nap runs up, the color is richer.

This designing and embellishment process remains her favorite aspect of the business, saying, “This, of course, requires careful construction and engineering so no element of sewing goes unturned with these projects. But my next favorite thing is teaching and energizing sewers of all ages to play creatively with fabric and make successful clothing.”

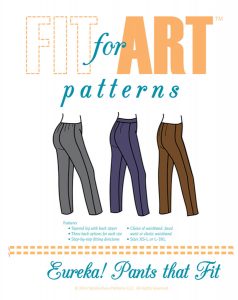

This designing and embellishment process remains her favorite aspect of the business, saying, “This, of course, requires careful construction and engineering so no element of sewing goes unturned with these projects. But my next favorite thing is teaching and energizing sewers of all ages to play creatively with fabric and make successful clothing.” In addition to her classes, you may recognize Rae’s name from the many fitting and design articles she has written for Sew News and Threads Magazines over the past 15 years. She says, “It has been such a pleasure to help women of all shapes, sizes, and ages to get a good fit and feel empowered to stitch up a wardrobe that fits their bodies and lifestyles.” In addition she is a favorite instructor at ASG chapters throughout the country and at our ASG annual conference.

In addition to her classes, you may recognize Rae’s name from the many fitting and design articles she has written for Sew News and Threads Magazines over the past 15 years. She says, “It has been such a pleasure to help women of all shapes, sizes, and ages to get a good fit and feel empowered to stitch up a wardrobe that fits their bodies and lifestyles.” In addition she is a favorite instructor at ASG chapters throughout the country and at our ASG annual conference.

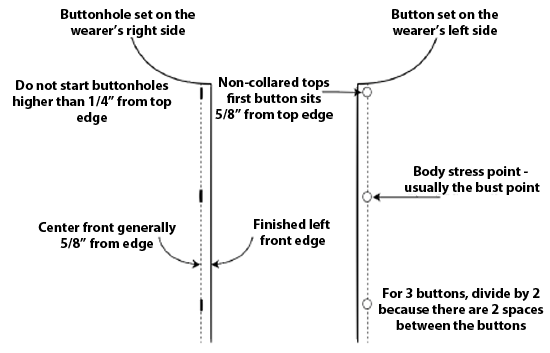

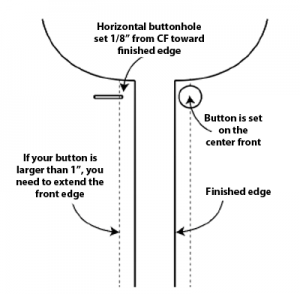

Button and buttonhole placements can sometimes be confusing. If the button and buttonhole are placed incorrectly, the garment may be too tight, too loose, or create gaping. The number of buttons on the garment is suggested on your pattern envelope, but it’s up to your personal preference or need. A good guide to start placing your buttons vertically is to keep in mind your body’s pressure points. Pressure points are where your body may put strain on the garment and may be your bust, belly, or even the hip if you are making a button front dress or skirt.

Button and buttonhole placements can sometimes be confusing. If the button and buttonhole are placed incorrectly, the garment may be too tight, too loose, or create gaping. The number of buttons on the garment is suggested on your pattern envelope, but it’s up to your personal preference or need. A good guide to start placing your buttons vertically is to keep in mind your body’s pressure points. Pressure points are where your body may put strain on the garment and may be your bust, belly, or even the hip if you are making a button front dress or skirt.