What’s’ your preferred method for cutting out projects—pins or pattern weights? There are sewists who swear by one or the other, but most of us tend to love both, depending on the fabric being used.

Pins hold pattern tissue firmly in place for cutting, but there are some fabrics where pins can leave permanent marks and, lo and behold, if you’re not pinning within the seam allowance, there could be those telltale marks. Vinyls and some faux suedes are prime examples of fabrics that benefit from the use of weights over pins.

Weights hold fabric flat against the cutting surface and if you cut with a rotary cutter instead of scissors, nothing moves. However, you do need to protect the surface with a special mat to avoid damage to the table top.

You can cut a weighted pattern with scissors, but it’s a bit tricky since the scissor blade tends to “pick up” the fabric as you cut, potentially shifting the weights around the perimeter.

In addition to eliminating the potential of pin marks, weights help secure slippery fabrics in place—a task much harder with pinned pieces that can slide around. Weights are also preferred on thick fabrics where pinning is near impossible—think wool coating or mohairs.

So, bottom line—there’s a place to use both methods of securing the pattern to the fabric.

Small weights can also be used at your machine to keep slippery fabrics from driving you crazy while seaming.

Let’s take a look at weights…

Many companies make pattern weights, from tiny rounds to large, heavy, flat metal rectangles used in the garment industry to secure multiple thicknesses on long tables.

Cast iron

If you’re cutting large pieces, like draperies or curtains, these iron weights can be handy for holding layers together without shifting. The raised handle makes them easy to move around as needed, and because of their weight, they stay in place with aplomb.

Glass

Circular glass weights are ideal for holding smaller spaces, and they have the advantage of being able to see through them in case you’re matching plaids, prints, etc. Just line up the pieces and weight them in place while you align adjacent pattern pieces.

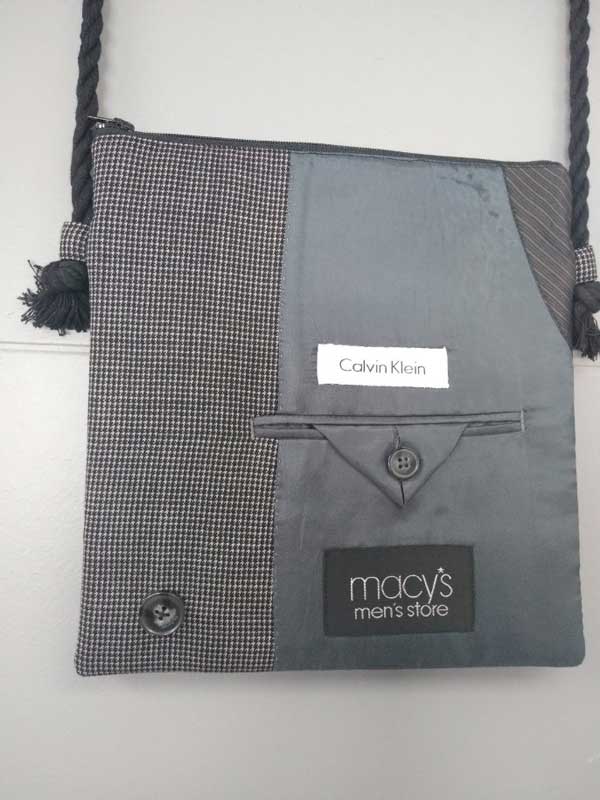

Fabric Bags

Weighted fabric bags in various sizes and shapes are another option for pattern weights. Usually filled with metal shot or shavings for weight, these handy little notions can be stacked atop each other if you need more weight in a particular area of the pattern piece you’re cutting.

DIY Weights

While available readymade, handy little fabric pillows or bags are easy to make yourself in any size or shape you need for your work. Just be sure the outer fabric is densely woven to keep the filler safely inside. If you use clean sand (from the pet store) or ground walnut shells for filler, it’s best to add a liner as well to ensure no leakage, but that’s not needed if you use metal shot or rice, beans, etc. for the weight you need.

- Other options suggested by guild members include using rolls of pennies for weight—especially handy for narrow pattern spaces like straps and facings, but note that they can roll too.

- Open the pantry and check out sardine and tuna cans for potential weights. While these are larger in size than many weights, they are readily available and of course the contents are edible after use in case it’s near lunch time. Can-size weights are better used with large patterns, like home décor items.

- Out on a beach walk? Pick up some large flat stones to create weights. Again, paintable for fun.

- Small ceramic tiles are also perfect for pattern weights. A tile store always has scrap pieces and sometimes they just give them away.

- Either covered or uncovered fishing weights are another DIY option—available in various shapes, sizes and weights depending on your needs.

- Head to the hardware store and look at flat metal washers—available in many sizes, these are ideal to use for pattern weights. For more fun, paint them bright colors, wrap them with yarn or fabric strips, or decoupage some fun fabrics to the surface.

Using Weights

- Just as we pin near the pattern edge, weights are best positioned in the same area. Depending on the shape of the pattern pieces and the weights, position the pieces near the corners for added hold.

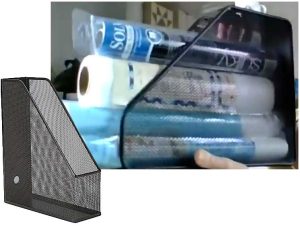

- If your fabric is larger than your cutting surface, use weights on the fabric around your pattern pieces to help keep it from sliding.

- Weights can also be used on paper—like for tracing patterns from a multi-size sheet master. They help to keep both from sliding and keep lines continuous.

~Linda Griepentrog Linda is the owner of G Wiz Creative Services and she does writing, editing and designing for companies in the sewing, crafting and quilting industries. In addition, she escorts fabric shopping tours to Hong Kong. She lives at the Oregon Coast with her husband Keith, and three dogs, Yohnuh, Abby, and Lizzie. Contact her at gwizdesigns@aol.com.

After breaking one of her embroidery hoops by laying it down on a table and then placing something on top of it, Rosemary from NJ bought a wreath hanger from a dollar store. She now slips the hanger over a door near her embroidery machine and actually remembers to place the hoops on the hanger when not embroidering. No more broken hoops!

After breaking one of her embroidery hoops by laying it down on a table and then placing something on top of it, Rosemary from NJ bought a wreath hanger from a dollar store. She now slips the hanger over a door near her embroidery machine and actually remembers to place the hoops on the hanger when not embroidering. No more broken hoops!