An upcycling article in Threads Magazine was the inspiration behind a member contest in the Central MA ASG chapter. Four chapter members participated in the contest and they were judged by two members the North New Jersey chapter, and one from the San Jose chapter. The criteria was to make a garment from one or two pieces of an existing garment. They could also use one yard of either purchased fabric or fabric from their own fabric stash. Read on to hear the members explain their projects:

An upcycling article in Threads Magazine was the inspiration behind a member contest in the Central MA ASG chapter. Four chapter members participated in the contest and they were judged by two members the North New Jersey chapter, and one from the San Jose chapter. The criteria was to make a garment from one or two pieces of an existing garment. They could also use one yard of either purchased fabric or fabric from their own fabric stash. Read on to hear the members explain their projects:

First Place Winner – Denise Carlson

I was entering this contest with a lot of apprehension because I rarely alter clothes as I don’t like to do so. I used two of my late father’s shirts. I am proud of myself for completely reconstructing his shirts to make it my own. The shirt “called” for different seam finishes. The shoulder seams were flat-felled and one side seam (which one of his shirts had), serged seams and the armhole has seam binding. I made a blind hem, and I inserted an invisible zipper in the side seam. I can honestly say that from start to finish, I truly did not stress about this. I took my time and very carefully documented all the pieces. I measured many times and placed the patterns on the fabric and then waited a day or two before deciding if I wanted to use it in that manner.

I drafted my front and side front from my sloper which I already had from my Master Seamstress classes and used my flat pattern book to design the front. I already had my princess seam pattern for the back. I combined the two to make my shirt.

Second Place Winner – Barbara Hendricks

Given the guidelines for the contest (2 garments only, 1 yard of stash fabric allowed), Barbara decided to use a pair of men’s jeans from her denim upcycle collection, a partial leather jacket which she had already used for the soles on baby shoes, and about a half yard of fabric from her stash for the lapels. She also had a navy blue separating zipper in her stash to use as well. Barbara made a vest from Simplicity Pattern #1499, which she had used previously which meant she didn’t have to purchase anything.

She began the project with the back of the leather jacket which was largely intact, so she cut the back of the vest out of that, lining up the pattern CB fold line with the center seam of the jacket; therefore, I eliminated the need to sew the center back seam by using the original one in the jacket. I followed the pattern instructions to a great extent, using known techniques for denim and leather, especially needle types and sizes.

The upper collar is cut from the leather and the under collar is denim. The separating zipper is asymmetrical and the lapel linings (exposed), made from a heavy weight woven print, fall nicely, complementing the leather and the denim.

This was a fun and creative project – I was very happy to participate.

Stacey Smith – Runner Up

I bought this suit at Salvation Army – it was originally bought at a well-known store in Worcester MA, “Shacks”, that went out of business recently. I used McCall’s pattern M5936, and every stitch of fabric from the suit for the jacket. I really enjoyed doing this upcycle project – it got me out of my comfort zone.

Melanie Dumas – Runner Up

My entry to the Upcycling Contest began as a cotton yellow floral sleeveless jumper which I had made years ago. I deconstructed it for use of the top of my contest dress. The maroon skirt of the dress is a peach skin fabric. The neckline and armholes were bound in coordinating bias tape.

I placed green peridot shaded beading on the hot pink floral centers of the dress’s top. This beading does sparkle in the appropriate lighting. The front of the top of my dress curves and flares to the sides while the back comes to a centered point.

I am going to make a summer wrap to complement the dress for a summer wedding.

~ Thank you to Denise Carlson, Central MA Chapter President for this submission

Not your typical marijuana plant, hemp can now be legally grown (within very specific restrictions) throughout the US. A more familiar use of this plant is as a source of CBD oil. And while it only captures a small portion of the textile market — less than 1% — it is also used to make fabric.

Not your typical marijuana plant, hemp can now be legally grown (within very specific restrictions) throughout the US. A more familiar use of this plant is as a source of CBD oil. And while it only captures a small portion of the textile market — less than 1% — it is also used to make fabric. It all starts with Mycelium; the fungus mushrooms are made of. When harnessed as a technology, it can be used to create everything from a plant-based steak to fabric. The cells are grown on beds of agricultural waste and the byproducts are compressed into an interconnected 3D network. Finally, it is tanned and dyed to create a product that resembles leather.

It all starts with Mycelium; the fungus mushrooms are made of. When harnessed as a technology, it can be used to create everything from a plant-based steak to fabric. The cells are grown on beds of agricultural waste and the byproducts are compressed into an interconnected 3D network. Finally, it is tanned and dyed to create a product that resembles leather. Fabrics are formed from a silk-like cellulose yarn made from citrus waste that can blend with other materials. When used in its purest form, the resulting 100% citrus textile features a soft and silky hand-feel, lightweight, and can be opaque or shiny.

Fabrics are formed from a silk-like cellulose yarn made from citrus waste that can blend with other materials. When used in its purest form, the resulting 100% citrus textile features a soft and silky hand-feel, lightweight, and can be opaque or shiny. While it may sound cutting-edge to create fabric from a banana plant, it was actually back in the 13th century when banana fiber cloth was first introduced in Japan. It comes from leave sheaths around the stem of the plant of abacá, a species of banana. The length of the fibers can be more than 3 meters long. Currently, it is being increasingly used in the manufacturing of garments, household textiles and upholstery thanks to innovations in the process of this fiber.

While it may sound cutting-edge to create fabric from a banana plant, it was actually back in the 13th century when banana fiber cloth was first introduced in Japan. It comes from leave sheaths around the stem of the plant of abacá, a species of banana. The length of the fibers can be more than 3 meters long. Currently, it is being increasingly used in the manufacturing of garments, household textiles and upholstery thanks to innovations in the process of this fiber. Often referred to as ‘pineapple leather,’ Piñatex® manufactures this material from the leaves of the pineapple, which are traditionally discarded or burned. There are several variations of the textile, with new developments for naturally dyed and 100% natural versions without the synthetic coating sometimes used to weatherproof the leather.

Often referred to as ‘pineapple leather,’ Piñatex® manufactures this material from the leaves of the pineapple, which are traditionally discarded or burned. There are several variations of the textile, with new developments for naturally dyed and 100% natural versions without the synthetic coating sometimes used to weatherproof the leather. “Wine leather” or “grape leather” transforms grape skins, seeds and stalks discarded during wine production from waste into a vegetal leather. And since 26B liters of wine are produced worldwide every year, the potential here is noteworthy.

“Wine leather” or “grape leather” transforms grape skins, seeds and stalks discarded during wine production from waste into a vegetal leather. And since 26B liters of wine are produced worldwide every year, the potential here is noteworthy.

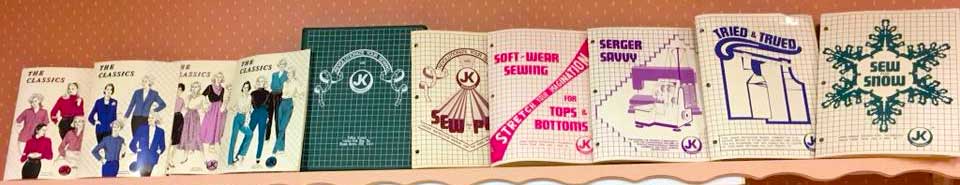

Thus began JKOriginals which consisted of several sewing seminars and ran from 1986 through 1994. The in-person classes covered jackets, blouses, skirts, and pants with easy to follow illustrations and creative ideas on redesigning these basics, as well as lessons on VHS tapes.

Thus began JKOriginals which consisted of several sewing seminars and ran from 1986 through 1994. The in-person classes covered jackets, blouses, skirts, and pants with easy to follow illustrations and creative ideas on redesigning these basics, as well as lessons on VHS tapes.

My local mechanic loves getting cotton weight fabric to use for rags. Anything that will sop up a spill or wipe off greasy hands is welcome. This helps him save the cost of buying rags, plus he then burns the used ones in his wood stove to heat his shop. Scraps — or even used clothing minus buttons, zippers, etc. — should be at least 12 inches square. Clean fabric that is sun faded, misprinted, or even stained works fine, and he doesn’t even mind wrinkles!

My local mechanic loves getting cotton weight fabric to use for rags. Anything that will sop up a spill or wipe off greasy hands is welcome. This helps him save the cost of buying rags, plus he then burns the used ones in his wood stove to heat his shop. Scraps — or even used clothing minus buttons, zippers, etc. — should be at least 12 inches square. Clean fabric that is sun faded, misprinted, or even stained works fine, and he doesn’t even mind wrinkles!